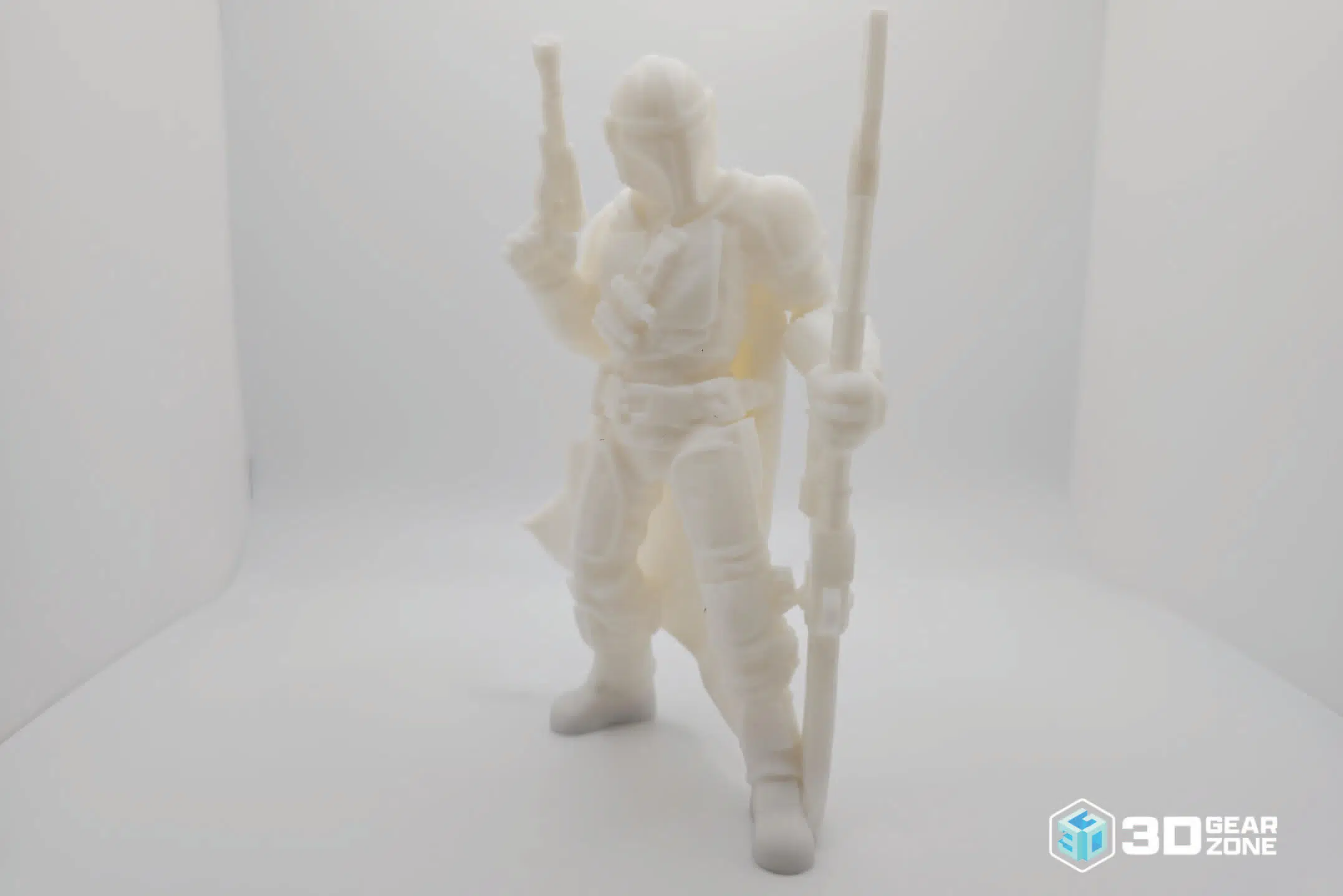

The Creality K1 is more than capable of producing amazing quality prints that rivals the best the consumer FDM 3D printer market has to offer. However, as a first generation machine, the K1 has a number of teething issues that Bambu Lab, its main competitor, had nearly a year to solve.

Creality Cloud

One of the next generation features of 3D printers is the inclusion of app or web browser integration. Creality’s answer to this is their Creality Cloud app. We have covered a previous version before in our previous Ender 3 S1 Pro review where we found multiple security issues and found it completely unusable. Unfortunately, not much has changed in this iteration.

While the app no longer prompts security warnings, it was replaced by an annoying large number of ads that popped up during start-up and throughout the app. Much of them are not-safe-for-work as well, and there is no ability to filter the content away. Creality also opted to use a premium currency system, restricting access to numerous models on the app through a paywall. Free users find themselves frequently encountering prompts to subscribe to the premium version of the app.

In short: Creality Cloud is completely unusable; do not install it. Instead, we say you use the desktop Creality Print to manage the K1 remotely.

Extruder and Hotend Issues

First generation hardware will always have issues that are only discovered with mass adoption. Creality is not alone in this—even the well-received Bambu Lab X1 Carbon required multiple revisions to its hardware before it was considered stable.

The first extruder and hotend that Creality has shipped with the K1 has reliability issues, specifically for the extruder. The original extruder shipped with the machine has a metal ring constructed out of cheap pot metal, which is prone to cracking. Users can identify a first generation extruder by seeing if the filament latch is shiny.

Meanwhile, the first generation hotend had a thermistor cartridge that was glued to the hotend and could potentially fall off over time. This hotend can be identified by the black silicone sock encasing it. Creality quickly replaced the extruder with a stronger metal ring denoted with a matte silver filament latch and the hotend with a properly integrated thermistor denoted with a red silicone sock. They have shipped these revised components to users who report their issues.

We ourselves experienced a failed first generation hotend but quickly received our revised hotend. We have had no issue with the machine since.

While it would have been better for Creality to ensure that its K1 has been fully tested and vetted before release, we do commend them for quickly acknowledging the issue and sending revisions to affected users.

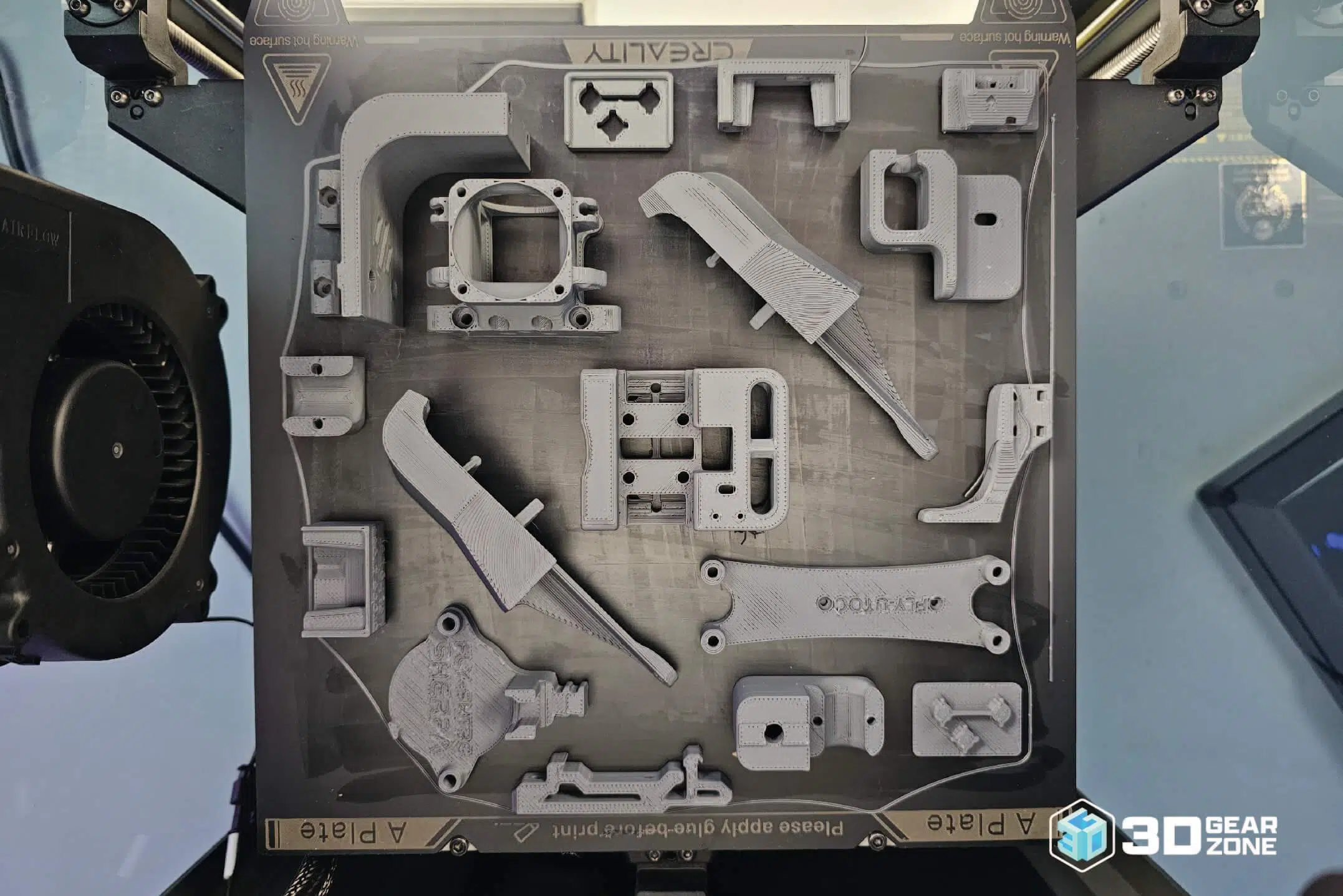

Polycarbonate Build Surface

The majority of modern FDM 3D printers feature a removable build surface coated in PEI. This allows for both great print adhesion along with easy part removal once the plate has cooled. Creality has chosen to use a polycarbonate coating on its removable print surface, which seemed like an odd choice to us. This setup was a popular choice in 2016 but fell out of favor with the advent of PEI surfaces.

Polycarbonate coatings offer extremely good print adhesion but at the cost of easy print removal. It is sometimes so difficult to remove that manufacturers suggest using a chisel. Users often resort to coating the build plate with a glue stick as a release agent. True enough, Creality bundled its K1 with a glue stick for this purpose.

After coating the build plate with glue stick, we found that prints from all filament types adhered extremely well and were quite easy to remove. However, we do feel that this is a step backwards in the user experience, as using glue sticks introduces an additional step, whereas PEI build surfaces achieve similar results with less effort.

Going Open Source

When Creality first released their K1 FDM 3D printer, they utilized a fork of Klipper firmware that was heavily restricted and modified to work with the K1 printer. As Klipper was an open source firmware developed by the 3D printing community, the community did not respond well to their firmware being taken, restricted, and closed off.

However, Creality eventually heeded to community pressure and released their fork of the Klipper firmware and gave root access to any user willing to experiment with. The community responded well to this change and promptly integrated the K1 to the increasingly popular OrcaSlicer.

As avid users of the Klipper firmware on multiple machines, this is welcome news and we hope the community is able to fully unlock the software potential of the Creality K1.

Setting Up Prints

Creality directs users to download its Creality Print slicer when the K1 is performing its initial setup. A massive advantage to directing users to a download page is that you will always have access to the latest revision of the slicer. In the past, companies often packaged their printers with a version of its slicer.

As of the time of the writing of this review, Creality has version 4.3 of its Creality Print slicer software.

Once installed, Creality Print will prompt the user to select the 3D printer they would like to set up. If the user selects a K1 series printer, it will also automatically detect and connect to the K1 if it is on the same wireless network.

Creality has a number of tuned print profiles for various filaments and brands. As part of the package, Creality includes a spool of its Hyper series PLA, specifically designed for high-speed printing. Indeed, by selecting the Hyper PLA, we experienced an impressive boost in print speeds, reaching up to 300mm/s. But for the purpose of this review, we will be using a stock profile. In subsequent evaluations, we will be comparing the Hyper series PLA to other filaments we had success with. You can find out some of the different kinds of filament we use for our tests and around our office here.

Creality Print is a customized version derived from the open-source Ultimaker Cura software, one of our favorites. However, Creality has introduced substantial thematic changes to the Cura base for its fork.

For users accustomed to Cura, the new layout might be disorienting, as numerous options are now tucked away in sub-menus and windows. Creality’s rationale for this adjustment is to avoid overwhelming new users with only the basic settings exposed. Advanced users can still access all settings and options available by clicking on the “advanced” tab or opening the “settings” window.

Overall, we found the Creality Print software easy to set up and slice. However, there was one critical bug we found: selecting tree supports crashed the program. Creality says they are aware of the issue, and reinstallation of the program typically solves this. In our experience, however, this did not solve the problem. We were forced to use standard grid supports when testing out Creality Slicer.

Like Bambu Lab, Creality offers a “one touch print” option where the file is sent to the K1, and it automatically starts printing it. We found this feature extremely user-friendly and easy to use.

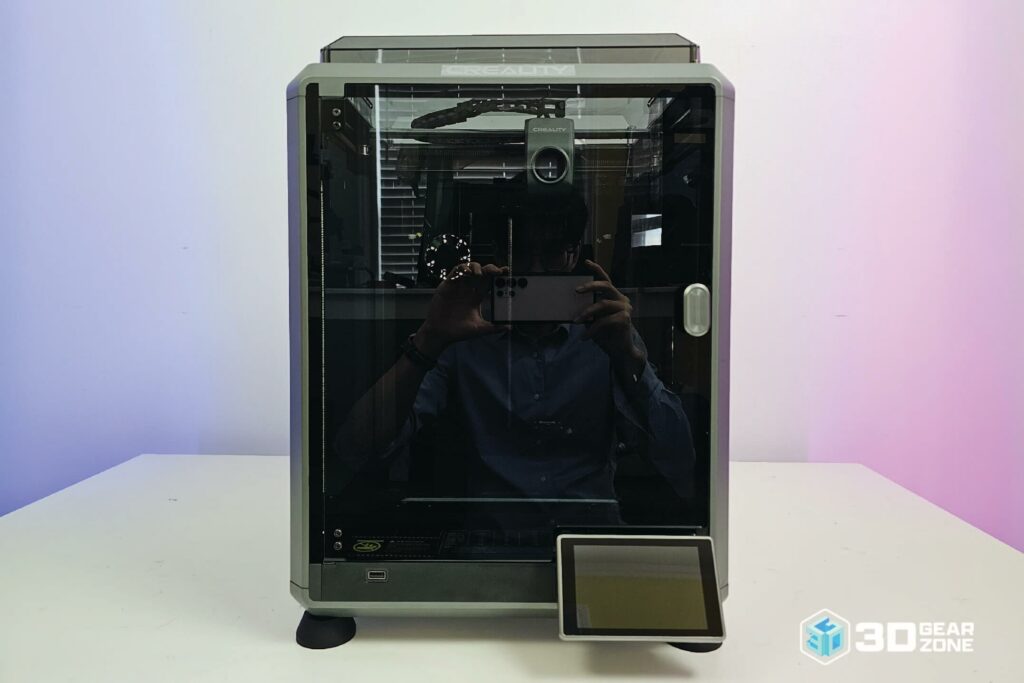

Alternatively, users can use the color touchscreen of the K1 to navigate and print files. Just like nearly all 3D printers in this class, we found the touch screen responsive. The UI was also very aesthetically pleasing and easy to use.

Noise Levels

One of the large advancements of FDM 3D printers over the years was the gradual reduction in overall noise. In particular, the introduction of the silent stepper drivers and higher quality fans made working in the same room as an operating FDM 3D printer tolerable. Whenever we reviewed printers like the Prusa MK3S and the Artillery Sidewinder X1, they were borderline inaudible with its noise output being less than 40db.

However, this new crop of FDM 3D printers, including the Creality K1, prioritized speed over noise levels. So, while the K1 still employs silent stepper drivers for its motion system, it is significantly louder compared to its previous generation machines when in motion. The primary contributors to this noise are the three fans within the machine and a large auxiliary blower positioned on the side of the 3D printer.

Our investigations demonstrated that the K1 generated over 70db of noise when the K1 operated at full speed, making it borderline intolerable for our team to be in the same room while the printer was in motion. This ranks as the loudest printer noise we’ve recorded among all the machines we’ve tested.