The Pros

- Great print quality

- Huge community and retailer support

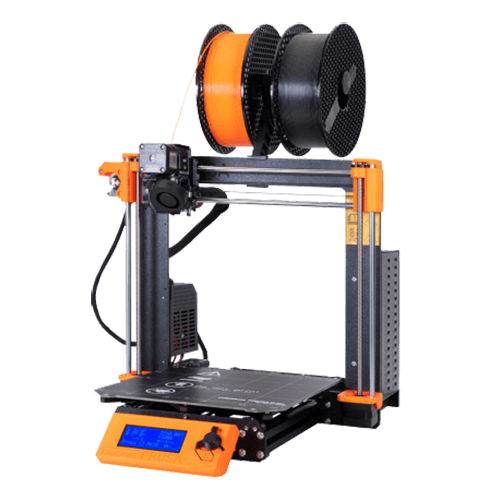

- More features than any other printers in its class

- Can be extremely quiet in stealth mode. One of the quietest printers we have ever test

- Very reliable and easy to use

The Cons

- Dated LCD display

- Fully assembled printer is expensive at $999

- Newer, inexpensive printers have caught up in print quality