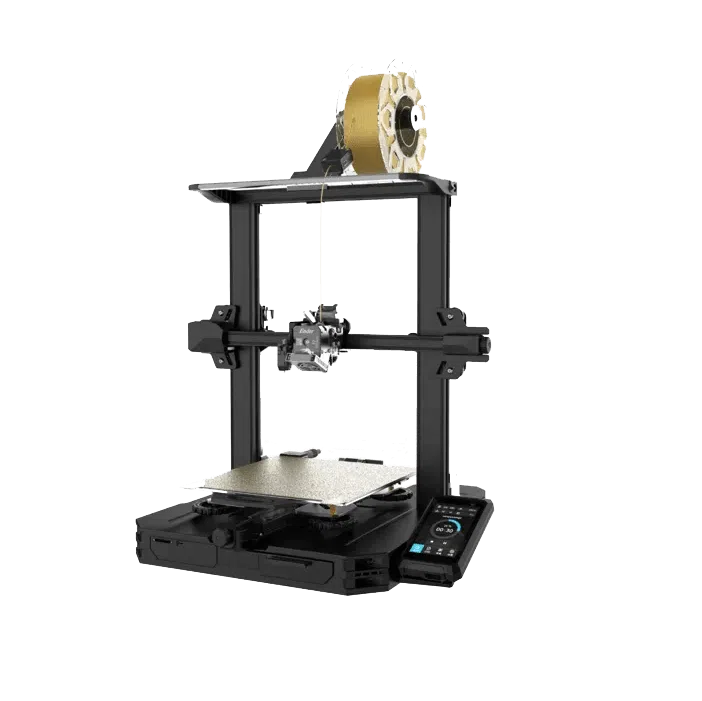

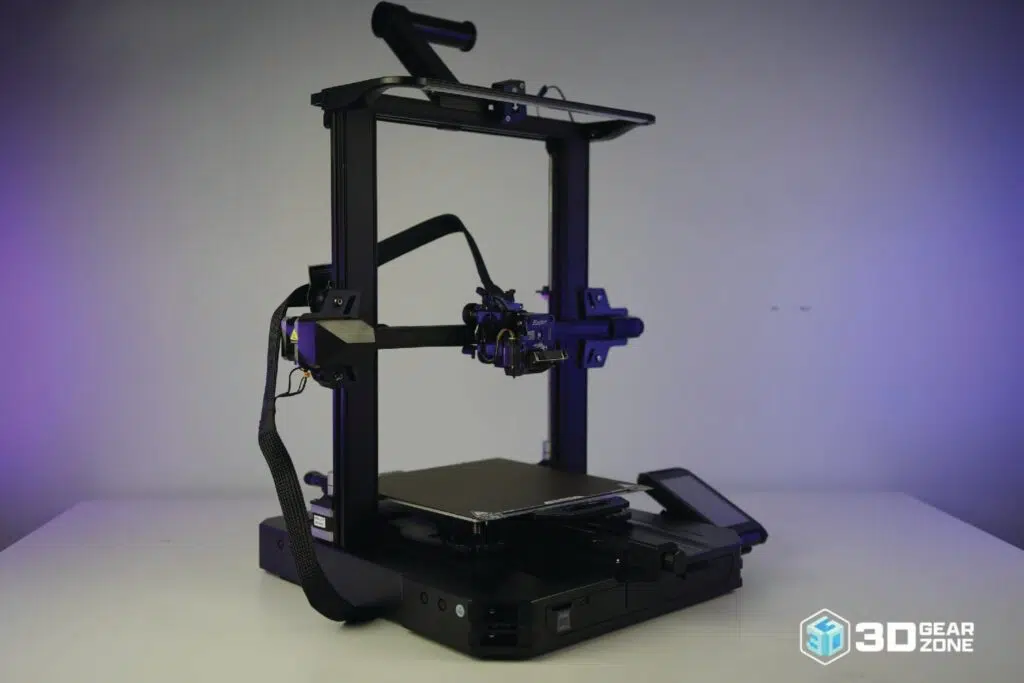

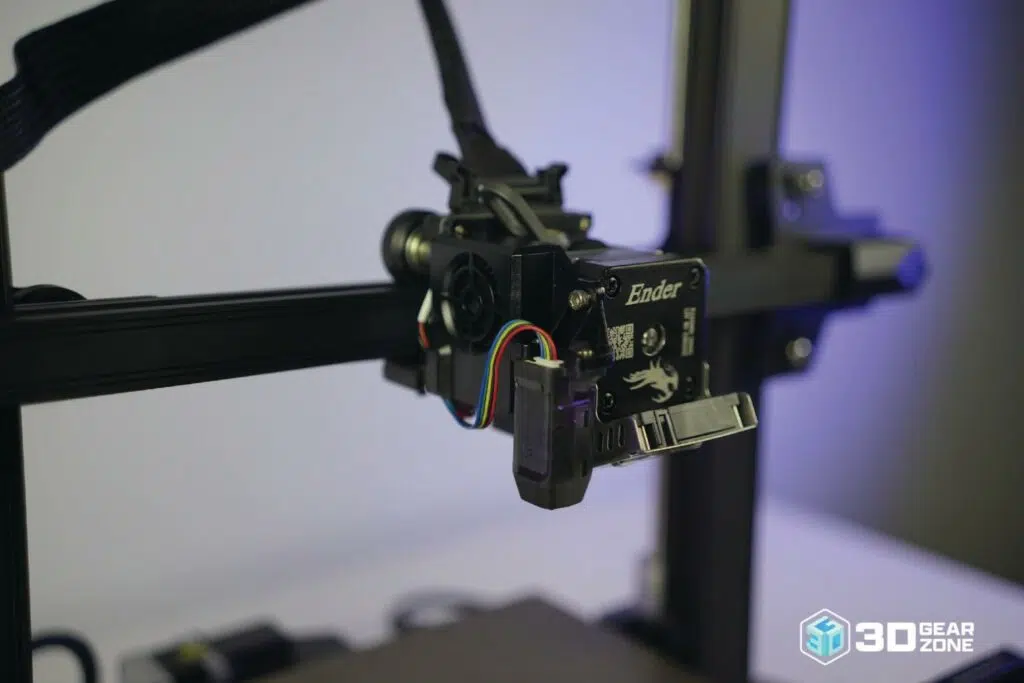

The Ender-3 S1 Pro’s Sprite direct drive extruder was a substantial shift away from the Bowden extruder used in countless other Creality printers, so we were pretty excited to test that out. After all, the sprite extruder promised improved print quality and the ability to print flexible filaments at speeds like TPU.

To put things to the test, we put the S1 Pro through our usual suite of test models that represent many objects that customers may print. This includes benchmarks such as the ubiquitous benchy, the calibration cube, and the z-banding tower. This is followed by figures and models such as the Mandalorian figure and the low poly Pikachu. Finally, we tested the S1 Pro’s ability to print flexibles (like TPU) by printing a cellphone case.

We tested the Creality Ender-3 S1 Pro in four major areas: its ability to resolve details, z-layer alignment, dimensional accuracy, and print repeatability. We used stock 0.2mm layer height settings shipped in Creality Slicer for all our tests.

Benchmarks

Printing the benchy and calibration cube was an easy task for the Creality Ender-3 S1 Pro. Our investigations demonstrated that the new Sprite direct drive extruder was indeed a great step up from the old Bowden extruder, with the benchy showing consistent extrusion and no visual artifacts. This was also the case with the calibration cube with its sharp corners and smooth walls. We even noticed improved dimensional accuracy, as the 20mm calibration cube measured 20.2mm (l) x 20.2mm (w), which was on par with any modern direct drive extruder we tested.

Initially, we had reservations about the small 4010-part cooling fan located at the front of the extruder. After all, many high-end 3D printers come equipped with either multiple fans or a larger 5015 blower fan that improves cooling performance by moving a larger volume of air. However, during our testing, we found that the 4010 part cooling fan performed well at stock settings.

Details

Next, we printed the Mandalorian figure, which puts the machine’s ability to print large amounts of details to the test. Unsurprisingly, the Ender-3 S1 Pro had no trouble faithfully reproducing the fine details in this model.

On the opposite end of the spectrum, we printed the low poly Pikachu. Featuring large flat sections that exaggerate layer lines or inconsistent extrusion, we often use this test to observe any poor-quality extrusions. However, with the Creality Ender-3 S1 Pro’s Sprite extruder, we were pleasantly surprised to see exceptional print quality. There were no extrusion artifacts, and the low-poly Pikachu came out looking great.

To test the S1 Pro’s z-alignment consistency, we printed a 250mm tall tube in vase mode. This test helps us assess the quality control and design of the z-axis assembly, which can greatly affect the z-axis consistency in 3D prints. “Z wobble,” or ribbing artifacts may appear if the lead screw in the z-axis is off or bent even slightly. However, with the S1 Pro’s dual z-lead screws and well-done factory assembly, we achieved a smooth tube with no z-layer issues, indicating excellent z-alignment consistency.

Lastly, we tested the Ender-3 S1 Pro’s ability to print flexible filaments using TPU filament to print a cellphone case. Printing with flexible filaments can be challenging, but the S1 Pro’s Sprite extruder handled it with ease. Modern direct drive extruders, including the one on the S1 Pro, excel at printing these difficult filaments. Even at its stock settings, we were impressed with this machine’s ability to print TPU filament and produce great results.