Quad Gantry Leveling

The flagship feature of the Voron 2 series and what draws users to this 3D printer is its quad gantry leveling ability. With four stepper motors positioned on each corner, the printer physically adjusts itself to align with the heated bed to ensure it is properly leveled. This sets it apart from most automatic bed leveling printers that rely on software to compensate for unevenly heated beds. This feature is especially advantageous for large and wide prints, as a physically leveled bed would yield smoother and flat bottom layers over software-leveled beds.

Out of all printers we have seen and used, only the Railcore and the RatRig 3 features a similar leveling system that physically adjusts the bed to align with the printhead.

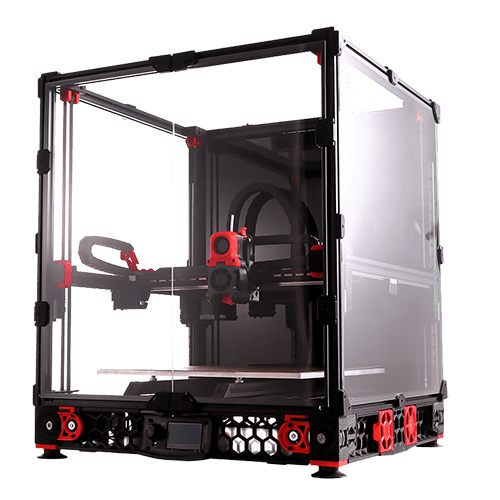

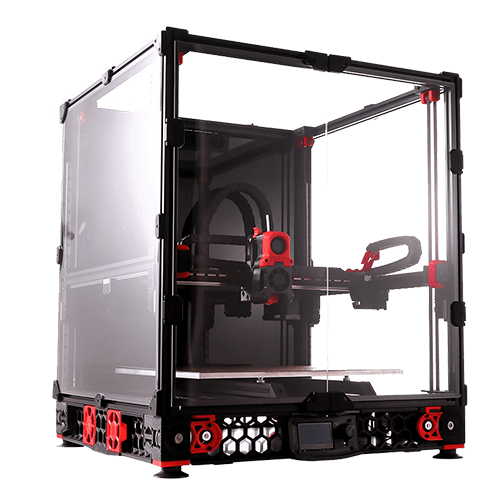

Fully Enclosed Print Area

Numerous high-performance filaments like ABS, nylon, and polycarbonate demand a fully enclosed space to counteract warping and potential detachment from the print bed. The Voron 2.4 comes with removable acrylic panels and doors to insulate the build volume, providing hard-to-print filaments with a warm environment for printing.

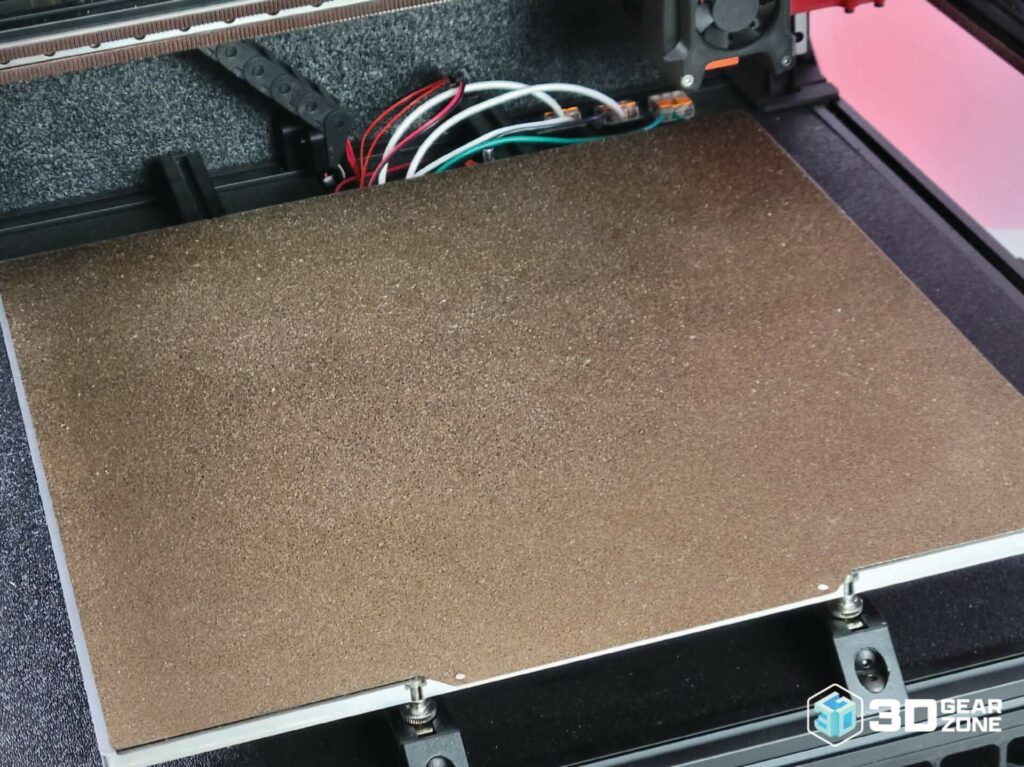

Flexible Removable Build Plate

The Voron 2.4 kit includes a versatile spring steel construction plate featuring textured PEI on one side and smooth PEI on the other. This flexible plate simplifies the removal of completed 3D prints—users can easily flex the plate, and the prints effortlessly detach. PEI is a reliable print surface, allowing prints to stick well to it when heated.

This flexible spring steel construction plate has a smooth and textured PEI surface that works well with various filament types, too. Smooth PEI is most commonly used for PLA, ABS, nylon, and polycarbonate filaments due to its exceptional adhesion properties. However, it’s not recommended for PETG and TPU since their strong adhesion could harm the build plate. Smooth PEI prints have a smooth and glossy surface on the bottom of the prints.

Because it provides significantly less adhesion, the textured PEI side is excellent for PETG and TPU filaments! The bottom of prints made with the textured PEI has a slightly rough and matte appearance.

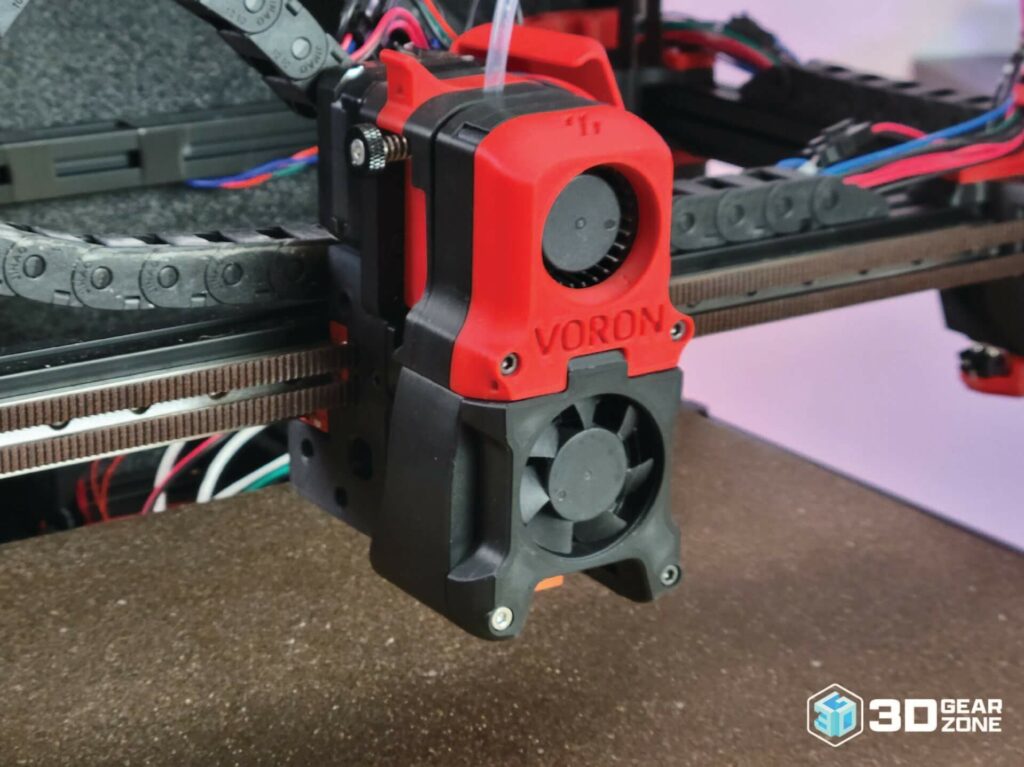

3:1 Direct Drive Extruder

A unique 3:1 direct twin drive extruder is included with the Voron 2.4. When compared to a normal single-gear extruder, a 3:1 drive gear ratio extruder has three times the pushing force (torque) needed to feed the filament into the hotend. This enables the Voron 2.4 to print extremely quickly and consistently. The Voron 2.4 can also print flexible filaments like TPU significantly faster than Bowden drive printers thanks to the direct drive extruder.

Hotend Made Entirely of Metal

The hotend of most consumer 3D printers is lined with polytetrafluoroethylene (PTFE). Because the plastic degrades quickly and generates poisonous gasses at higher temperatures, PTFE hotels limit the printing temperature to roughly 245-250°C. Printers with a PTFE hotend are unable to print with more exotic materials like polycarbonate and nylon due to their inability to print at higher temperatures. Fortunately, the Voron 2.4 boasts an all-metal hotend. This enables it to reach 280°C, making it suitable for printing exotic materials such as nylon and polycarbonate that demand higher temperatures.

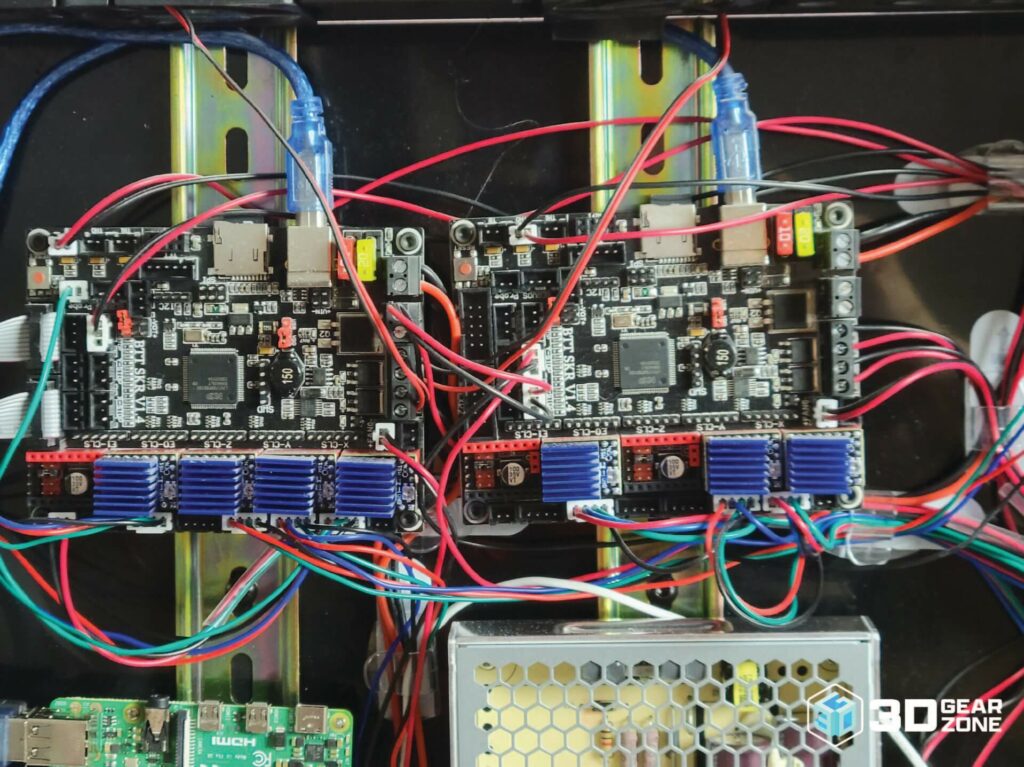

Wireless Connectivity with Octoprint

The Voron 2.4 comes with a Raspberry Pi microcomputer with an Octoprint web server installed. This setup offers great convenience, allowing users to remotely load, start, and monitor 3D prints via a web browser. Additionally, Octoprint’s functionality can be expanded by using plugins created by the 3D printing community. Users can easily add features like camera support or 3D print failure detection to the Voron 2.4 using these plugins if they wish.

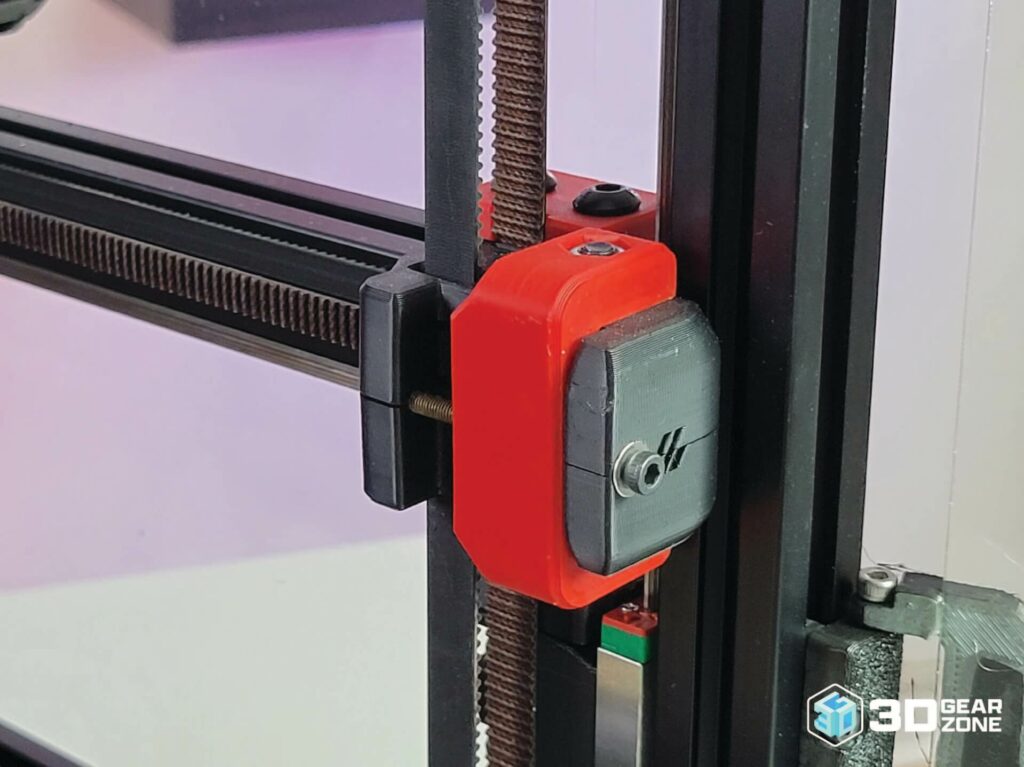

Belted Z Axis

Almost every 3D printer uses lead screws to move the printer up and down on the z-axis. It is an accurate, reliable, and inexpensive feature. However, for proper movement, lead screws must be perfectly straight, or it will introduce print artifacts. The Voron 2.4 avoids this issue entirely by using belts instead of lead screws to move the printer.

TMC 2209 Silent Stepper Drivers

The Voron 2.4 features TMC 2209 silent stepper drivers on all its stepper motors, making it very quiet when it’s in motion.