The Bambu Lab includes both input shaping and flow calibration, which, when together, promises great print quality. Coupled with its insane claimed speeds and multi-material system, we are extremely excited to see the prints coming out of the Bambu Lab X1 Carbon.

After all, if Bambu Lab can even come close to its claims, it promises truly next generation performance.

How we tested the machine

We tested the Bambu Lab X1 Carbon in four important areas: its ability to resolve details, dimensional accuracy, z-layer alignment, and print repeatability. For our tests, we used stock 0.2mm layer height and speed settings shipped in Bambu Studio.

We put the X1 Carbon through our usual gauntlet of test models that represent many objects that customers may print. This includes benchmarks such as the common benchy, the calibration cube, and the tall z-banding tower. This is followed by figures and models such as the Mandalorian figure and the low poly Pikachu. We also added an additional multi-color print test to best the AMS and its ability to print in multiple colors. You can find out some of the different kinds of filament we use for our tests and around our office here.

Results

With most modern 3D printers, printing industry benchmarks such as the ubiquitous benchy and calibration cubes should be an easy feat. Thus, we were unsurprised when the Bambu Lab X1 Carbon printed both flawlessly. However, what we were not expecting was how quickly the machine was able to print them.

Prior to 2022, a benchy typically takes 1-1.5 hours to complete for printers, and the Bambu Lab X1 Carbon was able to complete it in under 20 minutes. This represents a three to four times speed increase over the previous generation.

This quality and speed also extended to the printing of the calibration cube, which came out extremely clean and accurate—with sharp corners and no artifacts that could be seen. In fact, the 20mm calibration cubes measured 20.15mm x 20.2mm, making the X1 Carbon one of the more accurate printers we’ve tested with little adjustments.

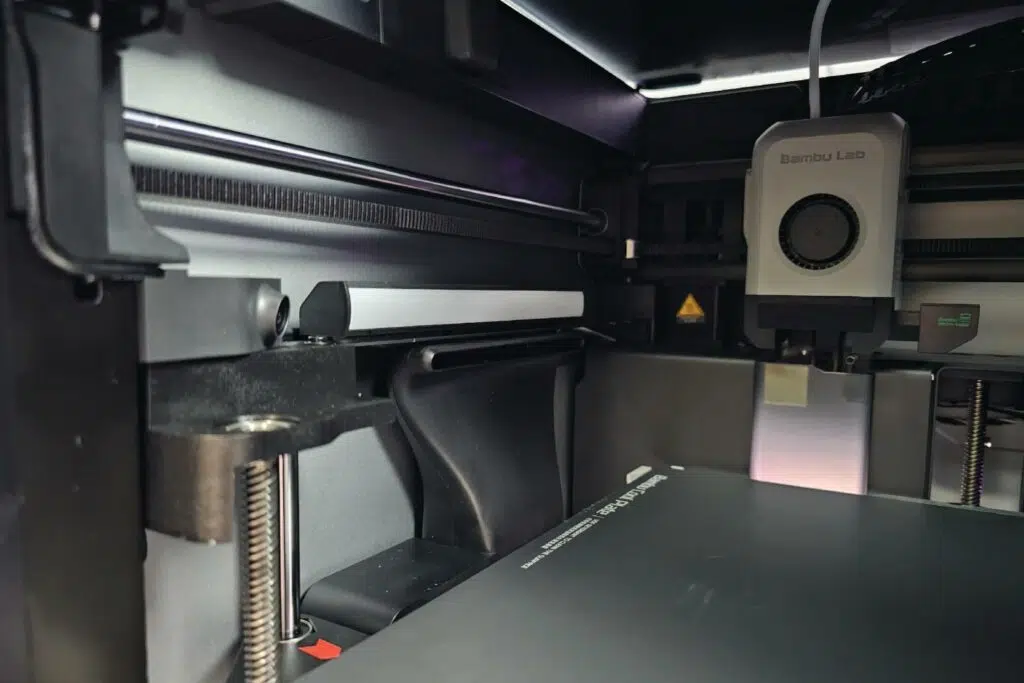

The Mandalorian figure is typically one of the more impressive prints in our testing suite and the Bambu Lab X1 Carbon did not break a sweat in printing it. All the details were faithfully reproduced and there was a distinct lack of ringing or ghosting on the model despite its incredibly high speed of printing. Its overhangs were clean and corners were pretty sharp, too. We suspect this is because of the massive auxiliary fan mounted on the right side of the printer. This loud fan blows a huge amount of air that quickly cools the molten filament which helps with the fine details.

The tradeoff to the above, however, is that quickly cooled filament potentially has worse inter-layer adhesion, which may result in more fragile prints. However, at the time of writing we have not tested this hypothesis.

Switching from highly detailed to less detailed, we then printed a low polygon count Pikachu. Since its simple geometry can highlight any printing artifacts, this cute model requires a highly tuned extruder to produce the best results. True enough, Bambulab’s default extruder settings were excellent. The test print displayed consistent extrusion and precise layering.

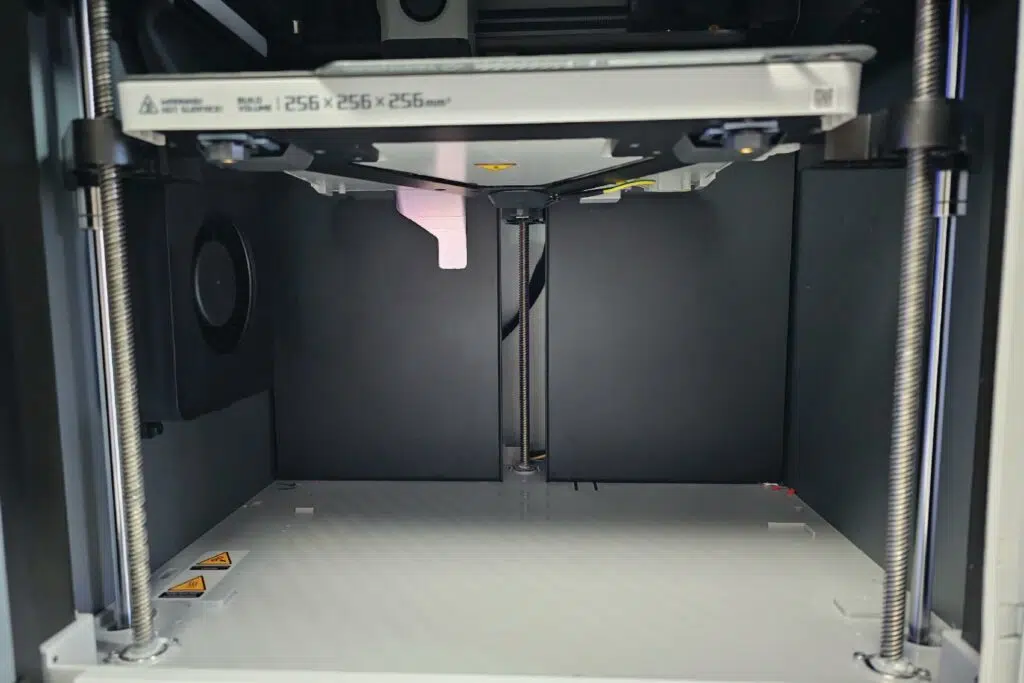

Finally, we tested the X1 Carbon’s z-layer height consistency by printing a 250mm tall tube in vase mode. This test exposes any issues in the z-axis assembly, providing insights into Bambu Lab’s quality control. Our evaluation showed that they have put considerable thought into the design and manufacturing of the z-axis assembly. The tube test print demonstrated no z banding or artifacts associated with z-axis issues.