The Pros

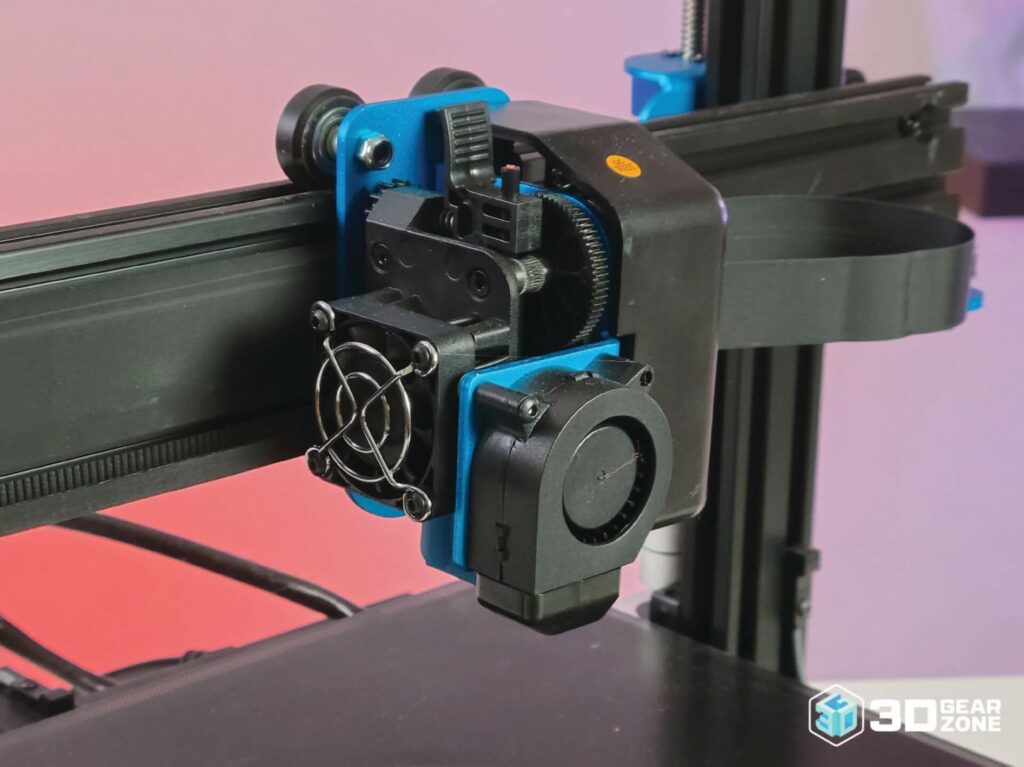

- Direct drive extruder and volcano style hotend for under $400. No other large format printer in its class has these features

- Prints well out of the box with no tuning

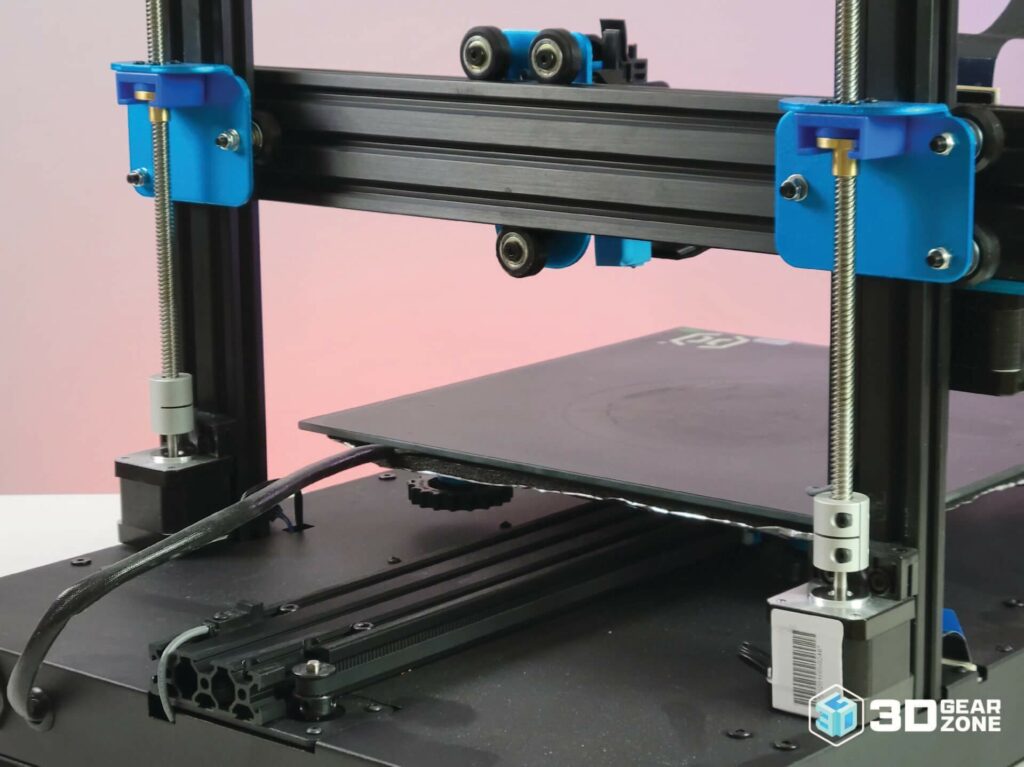

- Glass build plate provides good overall adhesion, making everyday printing reliable

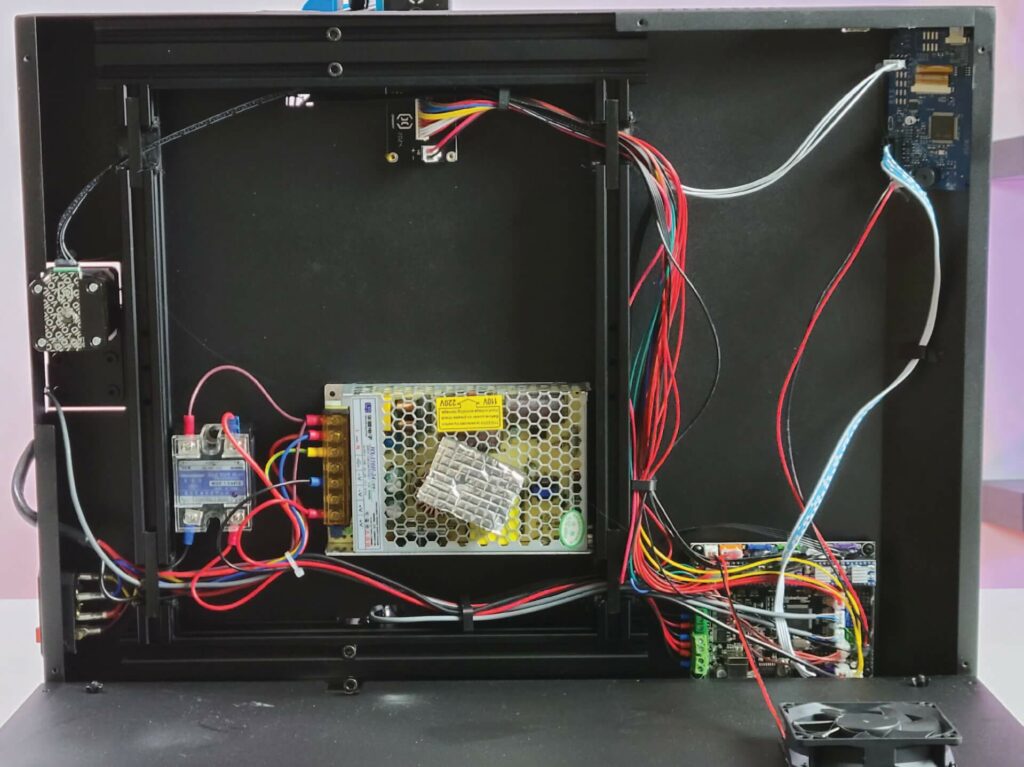

- Mains powered heated bed allows the printer to heat up very quickly

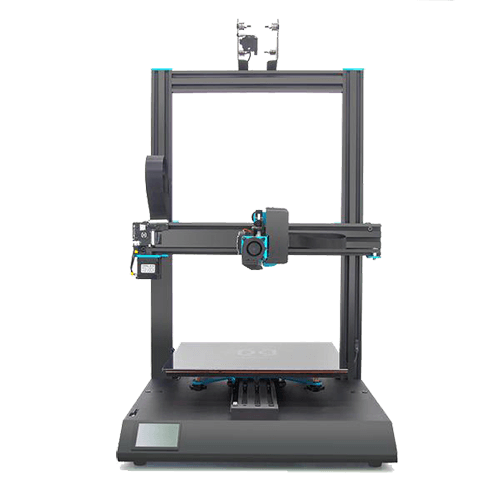

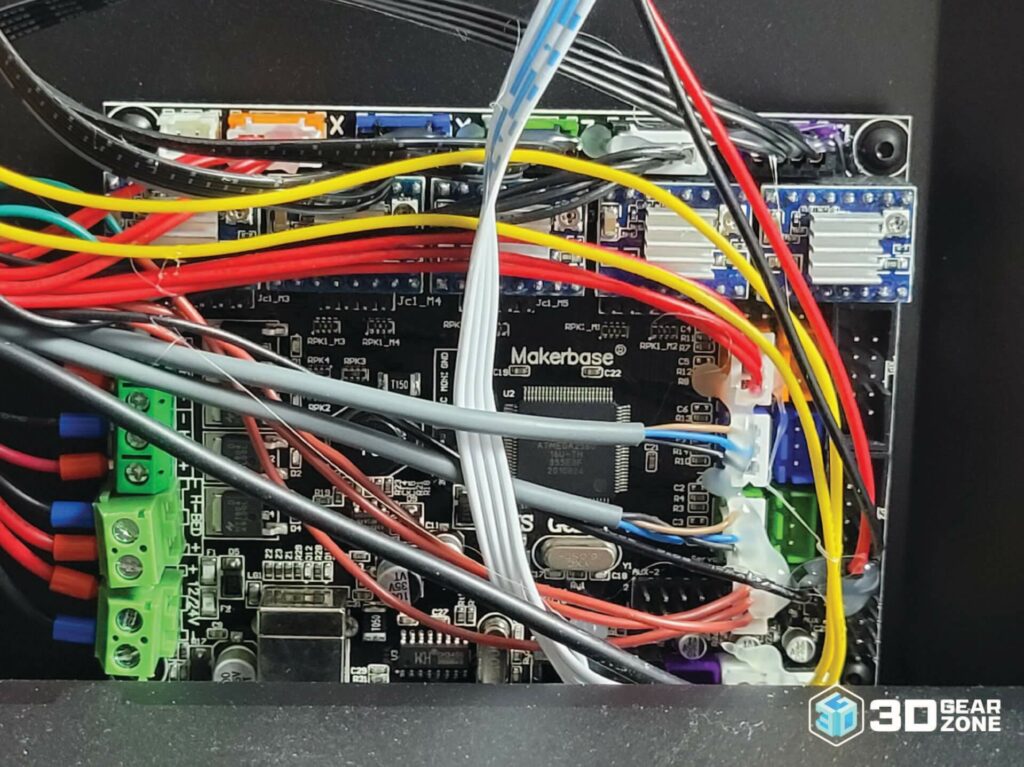

- Ribbon cables provide a very clean and professional aesthetic

The Cons

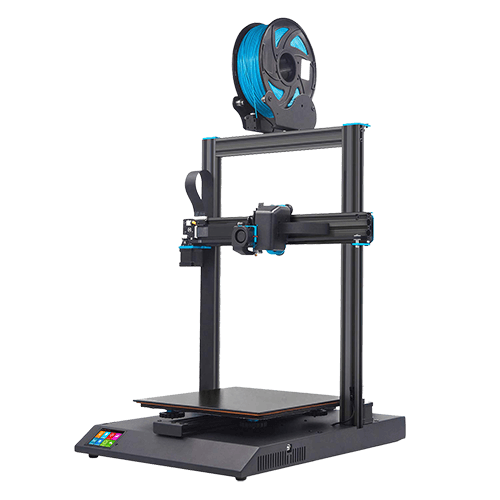

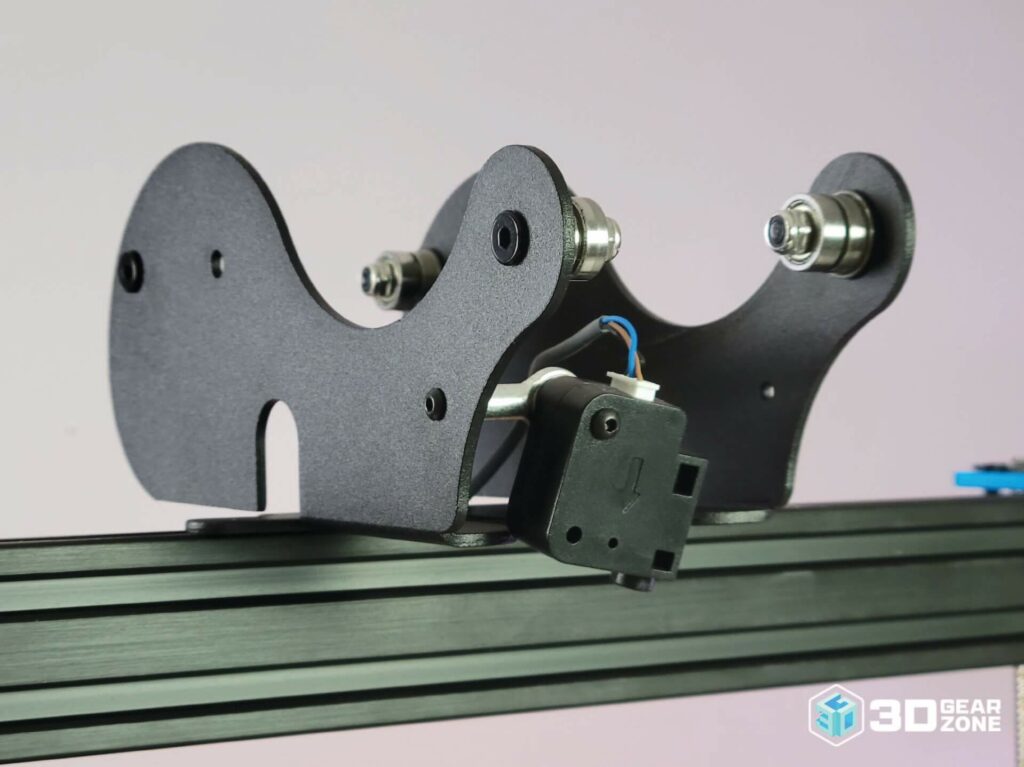

- Horrible spool holder design

- Heated bed has inconsistent temperatures near its corners. Corners are significantly cooler which may cause large prints to warp near the corner

- Some QA issues as some components may not be assembled correctly and some users have reported non-grounded units