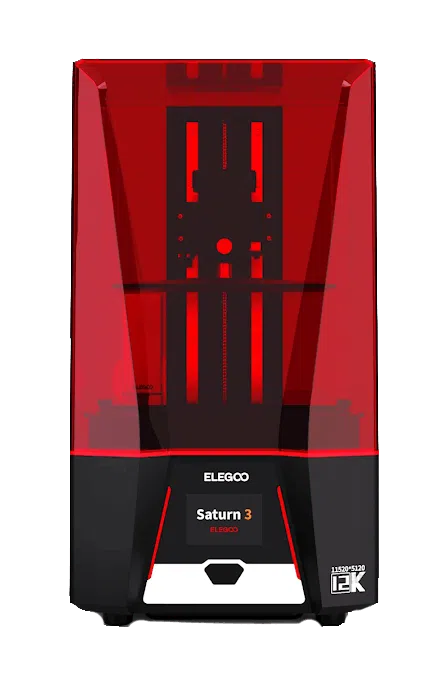

What sets a resin 3D printer apart from a traditional FDM 3D printer is its ability to resolve extremely small and precise details, making them perfect for figurines, miniatures, or jewelry. The Saturn 2 was equipped with an 8K screen that’s capable of resolving details as small as 29um, which is the best we have seen proper to the Saturn 3. The Saturn 3 is equipped with an eye-watering 12K, which has an even better 19x24um resolution. We ran an extensive array of tests to see if that translates to real-world improvements.

For the purposes of this review, we used ELEGOO’s 8K resin. These extremely high-resolution resin 3D printers require equally high-quality resins to highlight their ability to resolve extremely tiny details. We tested the Saturn 3 in three major areas: ability to resolve detailed models, z height consistency, and consistent UV exposure across its build plate.

With the advent of 8K and greater resolution LCD screens, the need for higher-quality resins has emerged to fully leverage the benefits of such high-resolution displays. However, at 12K resolution, we are now approaching the point of diminishing returns where it becomes impossible to see the difference in print quality with the naked eye.

Throughout our testing, we often compared the results of the ELEGOO Saturn 3 with its predecessor, the Saturn 2. Unsurprisingly, we discovered that the print quality difference between the two machines was exceedingly minimal. In fact, we had to employ a macro lens on our camera to discern any notable variations.

When we first trialed the ELEGOO Saturn 3, we started with 28mm miniatures that are commonly used for tabletop gaming. Unsurprisingly, the printed miniature is the best we have ever seen, thanks to incredibly high XY resolution. Every feather, spike, and tiny detail on the model was present, with no signs of voxels or layer artifacts. We continued printing tabletop models with a larger dragon bust. After conducting more experiments, we continued to be extremely impressed. The scale texture, teeth, and other extremely small details were reproduced with no issues.

Organic models

Organic models such as the dragon bust and the tabletop miniature represent one set of challenges for many resin 3D printers, the other being figurines featuring inorganic shapes such as robots and mechas. In the past, these types of prints often suffered from layer and voxel artifacts, which were particularly noticeable on flat surfaces and sharp corners. Fortunately, advancements in resolution have helped reduce the severity of these artifacts.

Our house test model combines both organic and inorganic shapes. It’s relatively large, too, with flat features (such as walls) and tiny organic features (such as rock and tile textures). Based on our observations, this difficult test model proved to be no issue for the Saturn 3.

Using the ELEGOO Saturn 3, we also printed a robot figurine with lots of pronounced edges and flat surfaces to highlight these issues. Our findings show that with the new 12K screen, these issues are all but gone. Again, we were really impressed with the level of quality that the ELEGOO Saturn 3 has brought to the table.

Tall objects

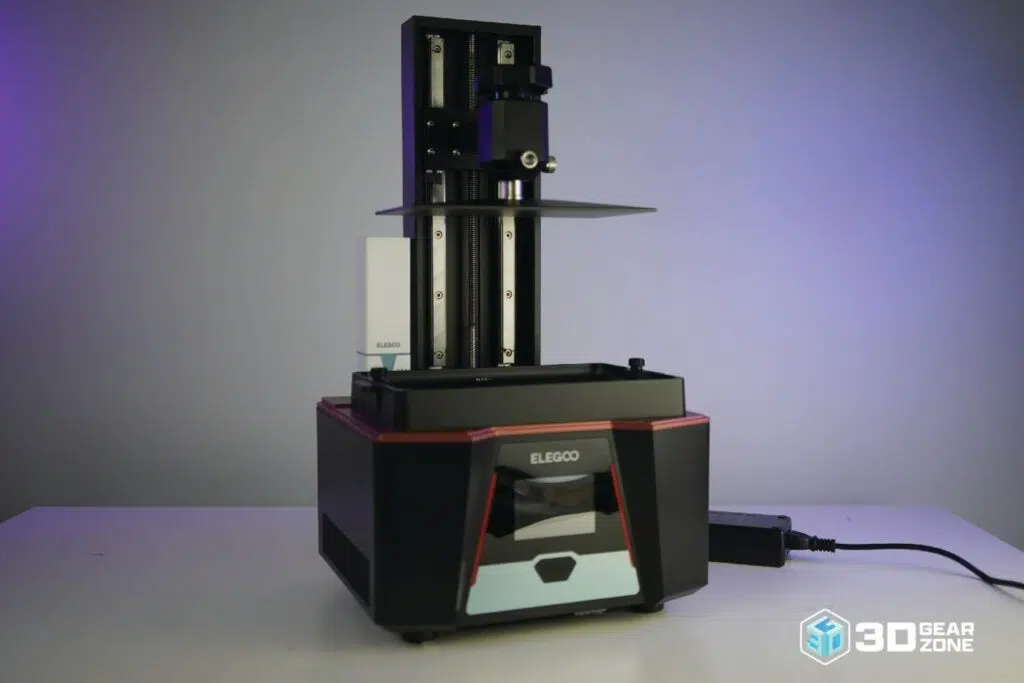

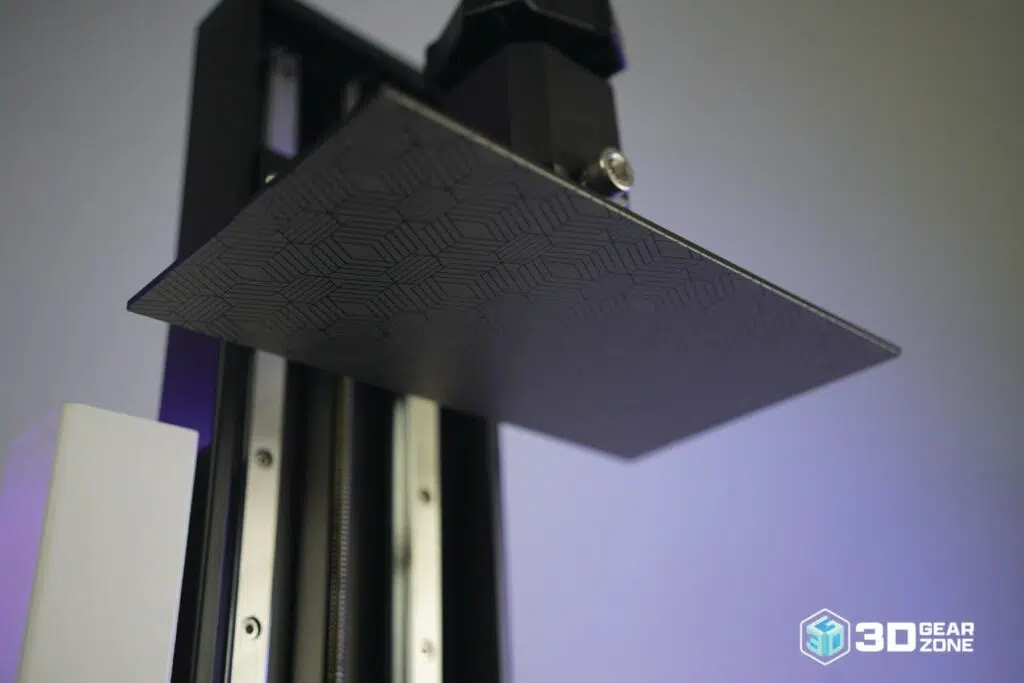

We later tested the Saturn 3’s ability to print tall objects and exaggerate any issues related to the z-stepper motor or with the linear rail on the z-axis. Given its robust metal construction and the presence of twin linear rails, we had high expectations for the Saturn 3’s performance in this aspect. We used the Eiffel Tower as our test model.

Our analysis revealed that the Saturn 3 performed admirably, successfully capturing and reproducing the small details of the tower with precision. We observed no issues with z alignment, which can be attributed to the printer’s sturdy construction and the inclusion of dual linear rails on the z-axis.

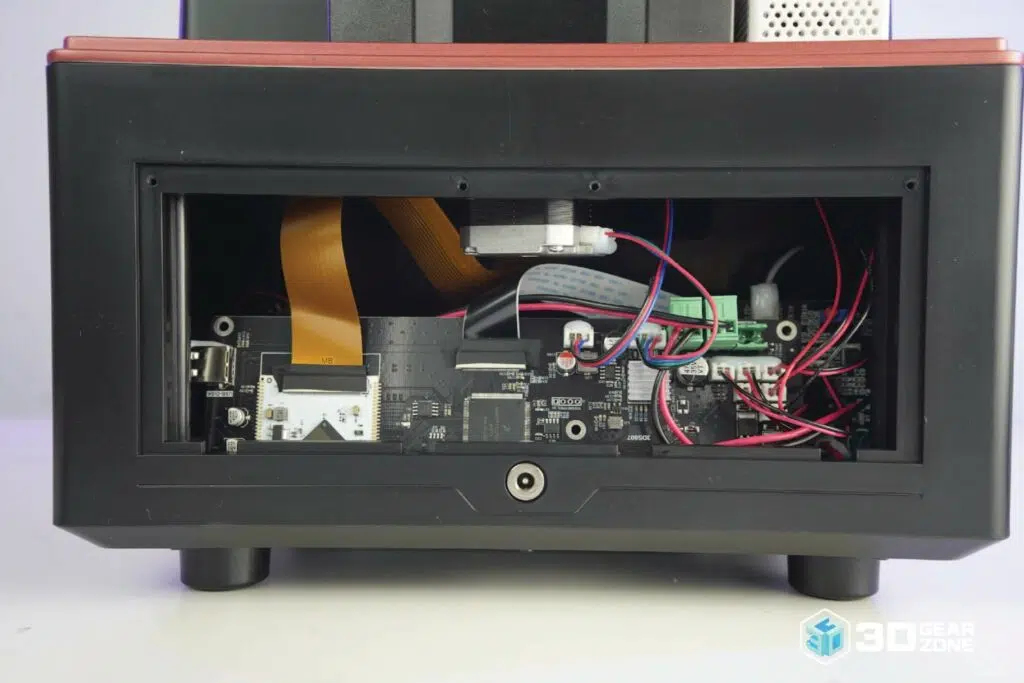

UV light distribution

For our last test, we printed a series of detailed tiles across the ELEGOO Saturn 3 to test how evenly the UV light is distributed across the build plate. If the light distribution is uneven, then details on the edge will look differently compared to the details in the middle. With such a large build surface, we were interested in how evenly lit the build area of the Saturn 3 truly is.

ELEGOO’s UV light system employs a series of lenses to ensure that UV exposure is uniform across its entire build area. They even claim it produces over 90% light conformity—which is all true based on our tests. The ELEGOO Saturn 3 outputs excellent quality prints that set the benchmark for medium format resin 3D printers of this generation.