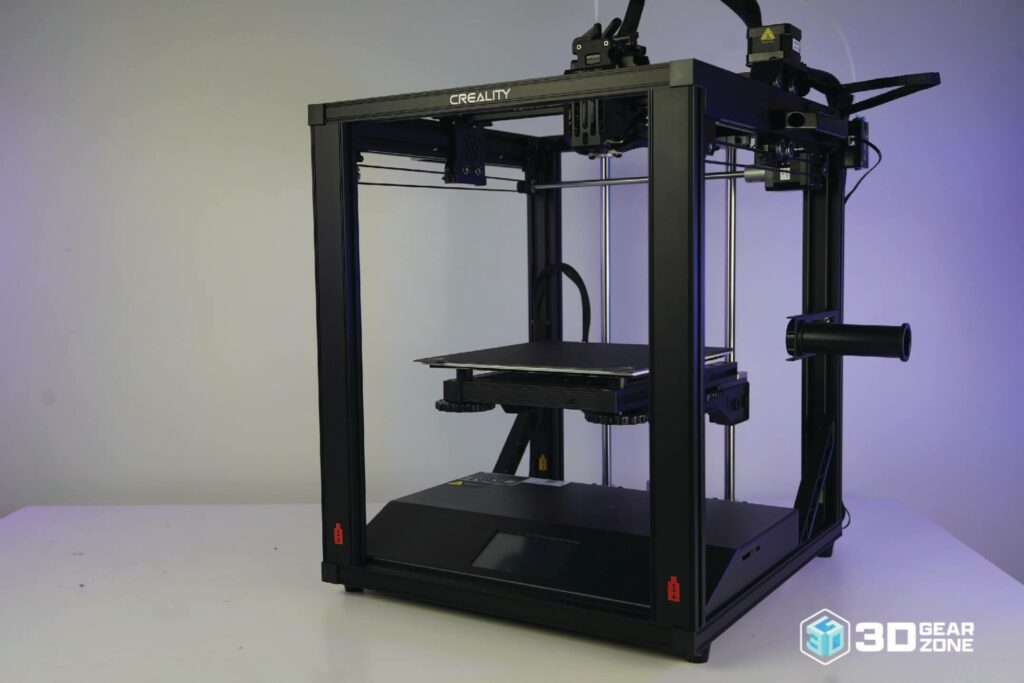

Coupled with its motion system and Klipper, the Ender 5 S1 promises the potential of high-speed, and high quality printing. In particular, we were pretty excited to test out the Sprite extruder and “improved” 5015 blower fan cooler.

How we tested the machine

We tested the Creality Ender 5 S1 in four important areas: the ability to resolve details, dimensional accuracy, z-layer alignment, and print repeatability. For the tests, we used stock 0.2mm layer height settings shipped in Creality Slicer.

We put the Ender 5 S1 through our usual gauntlet of test models that represent many objects that customers may print. This includes benchmarks such as the common benchy, the calibration cube, and the z-banding tower. This is followed by figures and models such as the Mandalorian figure and the low poly Pikachu. Finally, we used a cellphone case model to test the Ender 5 S1’s ability to handle flexible materials such as TPU.

Because we used the Creality Sonic Pad, we deviated from our usual methodology of just using the stock profiles on Creality Slicer. Ordinarily, the Ender 5 S1 comes with default print profiles that have a print speed of 50mm/s. However, we increased it to 100mm/s to see how much of a print speed improvement Klipper brings to the table.

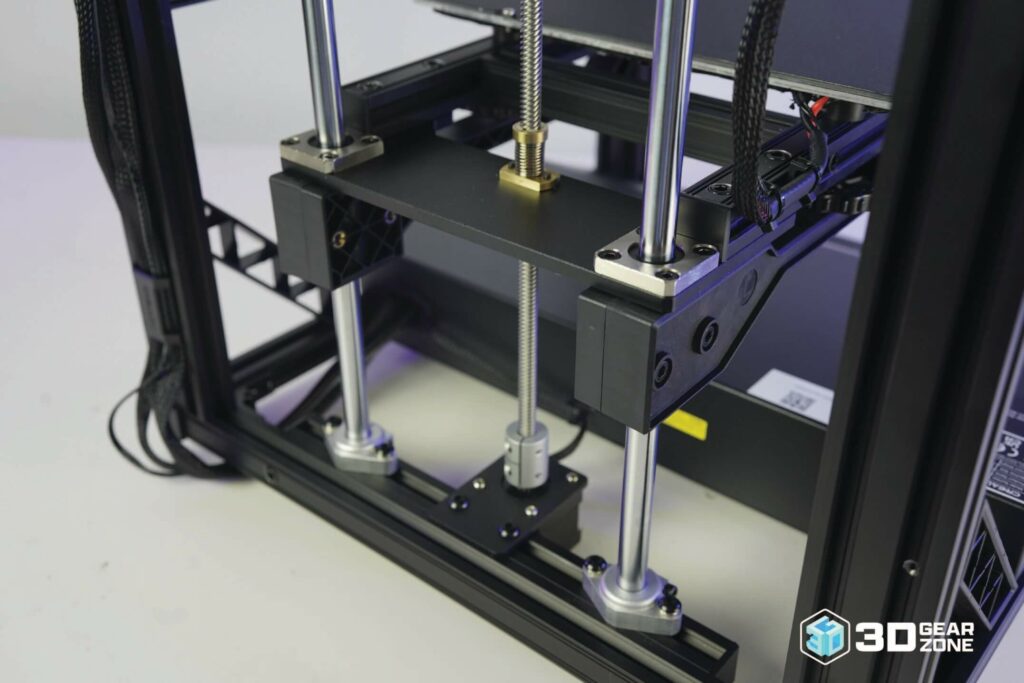

To test the Ender 5 S1’s z-alignment consistency, we printed a 275mm tall tube in vase mode. Quality control and design of the z-axis assembly dictates the consistency of the z-axis of a 3D printer. If the lead screw in the z-axis is off or bent by even a fraction of a degree, ribbing artifacts (known as “z wobble”) will appear on the 3D print. Tall and smooth objects like a tube will highlight any z inconsistencies on a print and will reveal quality control or assembly issues of a 3D printer.

Results

Printing the benchy and calibration cube was an easy task for the Creality Ender 5 S1. Our investigations demonstrated that the new Sprite direct drive extruder was a great step up from the old bowden extruder, with the benchy showing consistent extrusion and no visual artifacts.

This was also the case with the calibration cube with its sharp corners and smooth walls. Notably, the 20mm calibration cube measured 20.2mm (l) x 20.2mm (w), which was on par with any modern direct drive extruder that we have tested. We then repeatedly printed the calibration cube to test its print consistency and found that there were virtually no differences between all the calibration cubes.

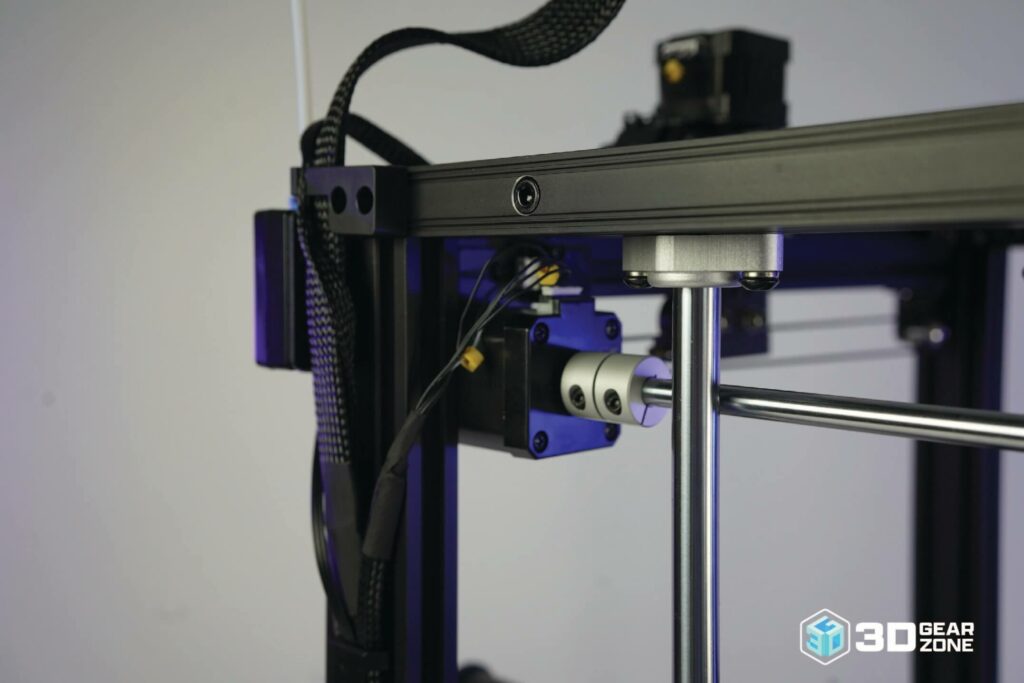

The 5015 blower fan included on the Ender 5 S1 is a huge improvement from the much weaker 4010 radial fan found on the majority of Creality printers. This is further improved by the injection molded fan duct that blows on both sides of the hotend nozzle to ensure that the molten plastic is evenly cooled from all directions. When printed at the 100mm/s speeds that we used throughout our Ender 5 S1 testing, the printer was able to adequately cool prints, resulting in sharp corners and well-formed overhangs and bridges.

We next printed the Mandalorian figure, which puts its ability to print large amounts of details to the test. Our analysis of this product revealed that the Ender 5 S1 had no trouble faithfully reproducing the fine details in this model.

On the opposite end of the spectrum, we printed the low poly Pikachu. Featuring large flat sections that exaggerate layer lines or inconsistent extrusion, we would be able to observe any poor-quality extrusions. Based on our observations, the S1 produced an extremely high-quality low-poly Pikachu with no extrusion artifacts.

Finally, we tested the Ender 5 S1 Pro’s ability to print flexible filaments. We opted for it to print a cellphone case in TPU filament, as mentioned above. Most modern direct drive extruders excel in printing difficult filaments (TPU for our tests), and the S1 Pro’s sprite extruder was no exception. We found that the Ender 5 S1 can print TPU filament relatively quickly at 50mm/s. And while the Ender 5 S1 is especially susceptible to z wobble due to the unsupported single z axis, our findings show that the Ender 5 S1 had no issues with z wobble throughout our tests.