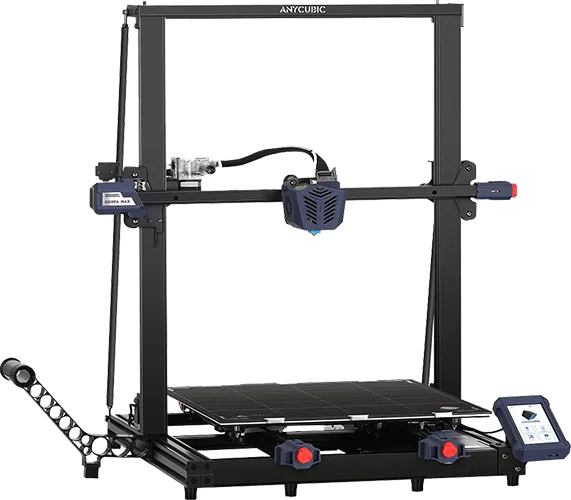

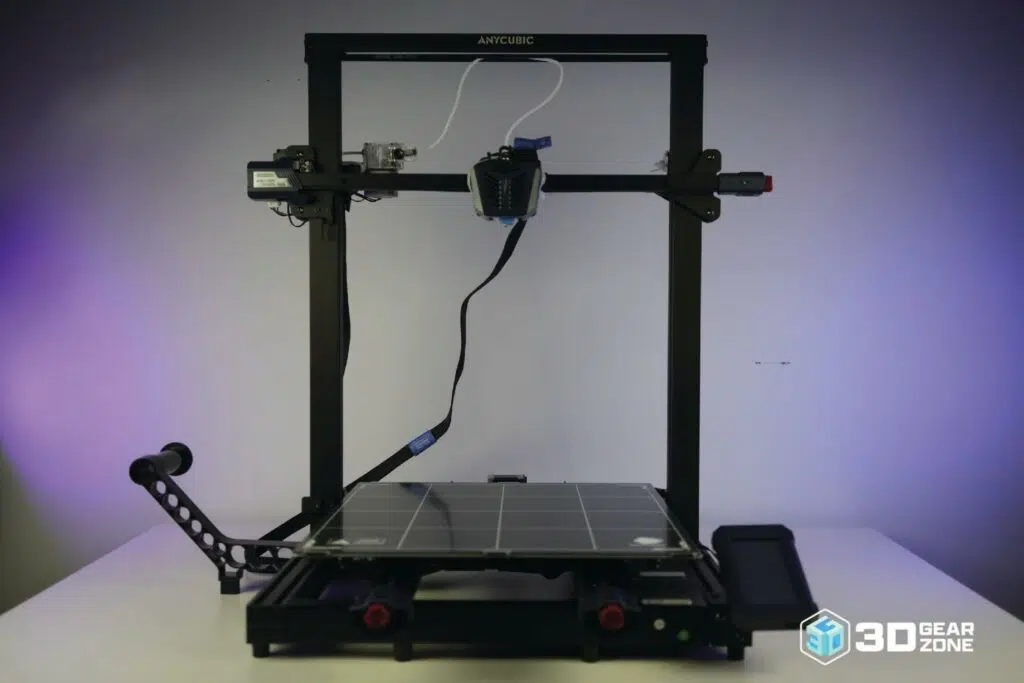

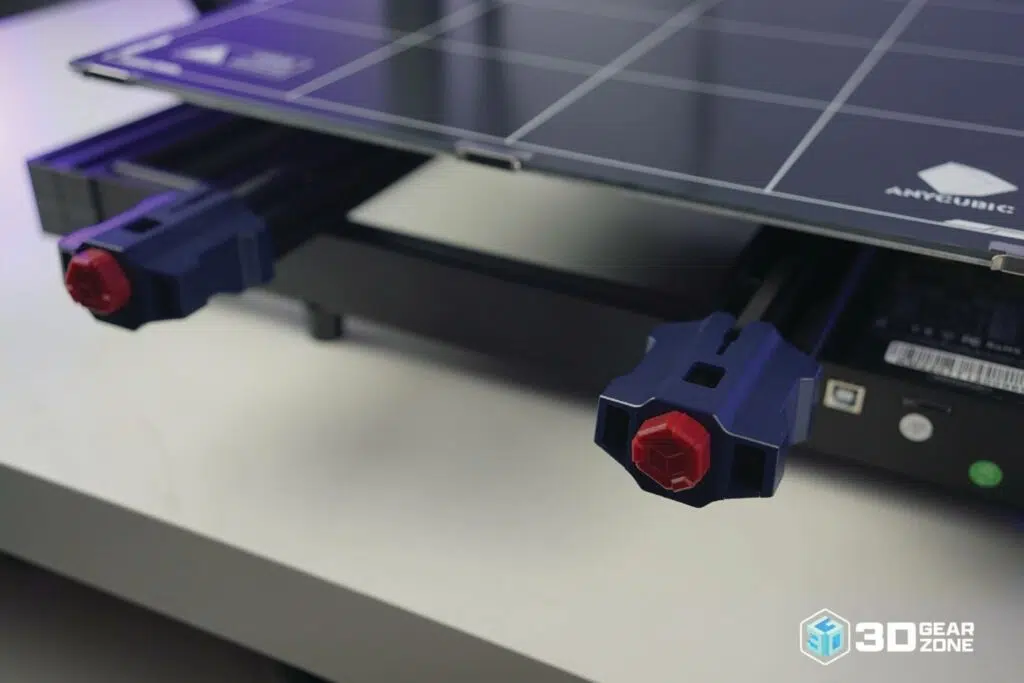

The Kobra Max is geared towards extremely large 3D prints, offering a generous build volume of 400mm (l) x 400mm (w) x 450mm (h). We were eager to print large armor pieces alongside our usual gamut of test prints like calibration cubes, towers, and Mandalorian figures.

Initially, we were not able to test the machine’s ability to print small or large objects at the beginning due to the printer constantly jamming or clogging. It appears that the temperature readings from the hotend were inaccurate, with the actual temperature being 20-30 degrees Celsius higher than what was reported by the printer. This would cause our PLA filament to overheat and jam within the Kobra Max’s hotend. To overcome this problem, we adjusted the printing temperature to 180 degrees Celsius instead of the default 200 degrees Celsius, which allowed us to successfully complete our test prints.

We tested the Kobra in four major areas: the ability to resolve details, z-layer alignment, dimensional accuracy, and print repeatability. For the tests, we used stock 0.2mm layer height settings in the shipped Cura 4.2.

Basic test prints

Our basic tests involve printing a large variety of models to analyze the Anycubic Kobra Max’s ability to resolve large and small details. This involved printing models like the calibration cube, Benchy, and the Mandalorian figure. Unfortunately, we observed issues such as blobs, stringing, ringing, and inconsistent extrusion across all these models. As a result of our tests, it became evident that the Kobra Max falls short in terms of print quality, displaying subpar performance.

Anycubic has also equipped the Kobra Max with a volcano-style hotend, which offers the advantage of higher filament melt rates and the potential for faster printing or larger layer heights. On paper, this sounds great. However, the massive moving build plate of the Kobra Max limits the overall speed of the printer.

This highlights one of the major downsides of a volcano-style hotend: slow speeds can lead to decreased print quality. When the hotend doesn’t move fast enough, molten plastic can ooze out, causing issues like stringing and blobs at sharp corners or intricate details in the print. While this is bad for anything that requires sharp details, this is even worse for prints that require high dimensional accuracy.

To prove this, we printed around ten 20mm calibration cubes. Due to excessive blobbing on the corners, the machine produced some of the most inaccurate calibration cubes we have ever printed. At 20.4mm (l) x 20.6mm (w), the Kobra Max struggled to print objects that required any sort of dimensional accuracy. For comparison, most modern 3D printers are capable of producing calibration cubes at a much more accurate 20.2mm (l) x 20.2mm (w).

Large test prints

One unique print that we tried on the Kobra Max was a piece of Star Wars armor. Given the printer’s large format, it seemed like an ideal fit for such a project. But while we were able to complete the armor print, we encountered similar issues with print quality, including stringing, blobs, and ghosting.

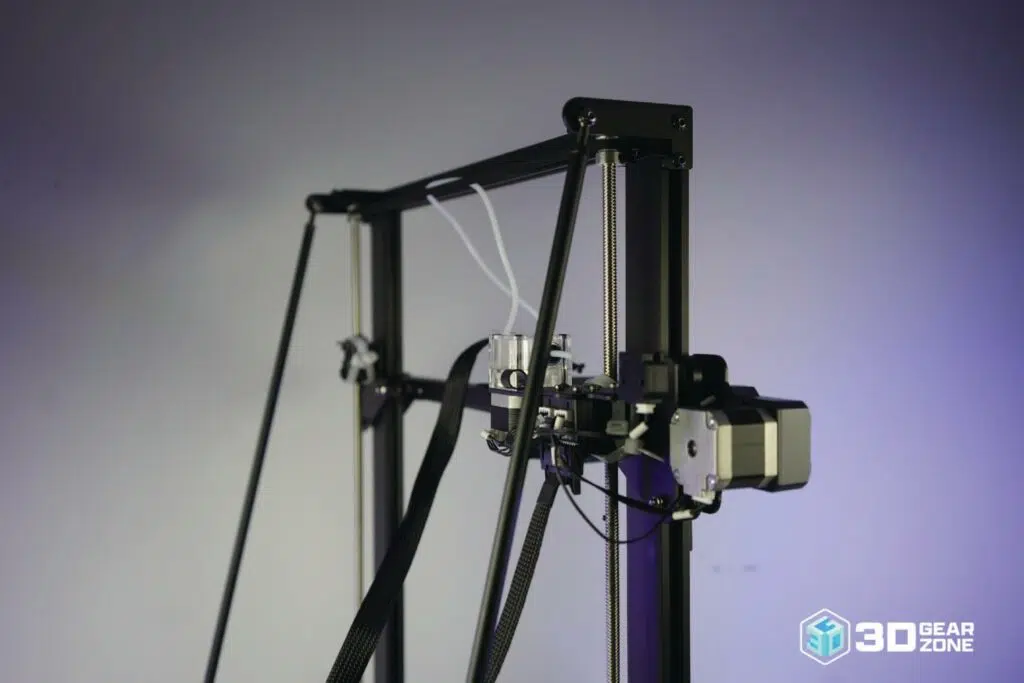

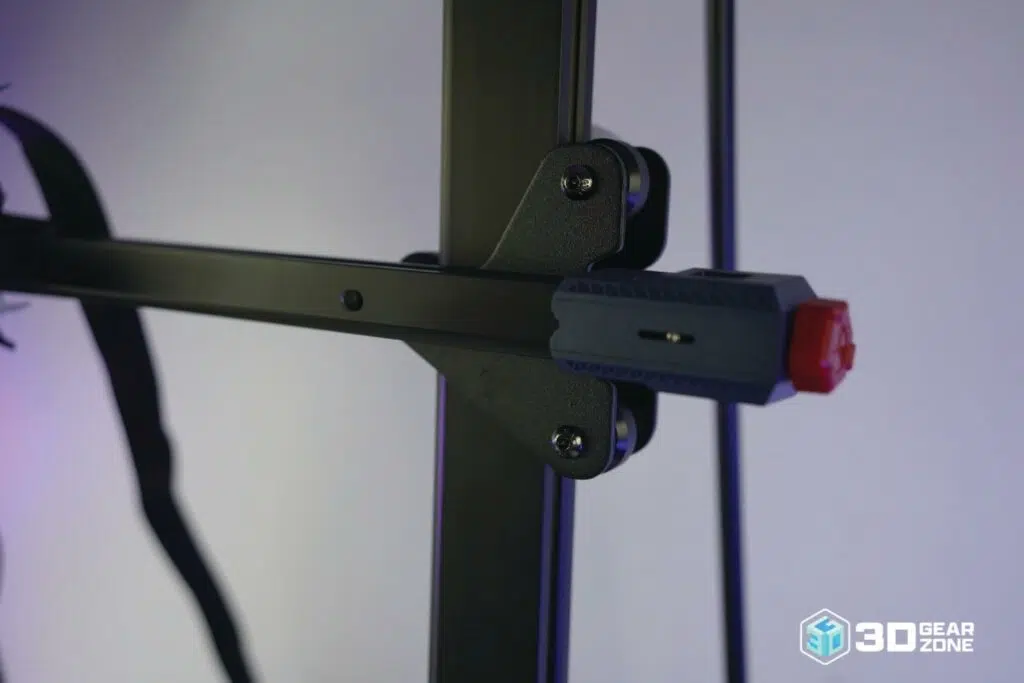

We tested the z-layer alignment consistency of the Kobra Max by printing an extremely massive 430mm tall tube. This test allows us to assess the quality control and design of the z-axis assembly, which plays a crucial role in ensuring consistent z-axis movement. If the lead screw in the z-axis is off or bent by even a fraction of a degree, ribbing artifacts (known as “z wobble”) will appear on the 3D print. Tall and smooth objects like a tube will highlight any z inconsistencies on a print and will reveal quality control or assembly issues of a 3D printer.

Anycubic’s floating nut design on its z lead screws did the trick in eliminating z artifacts. This is one area that Anycubic should be given a lot of credit for.