The Pros

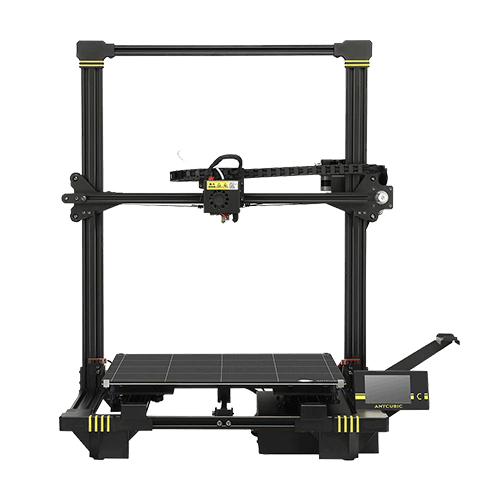

- The most affordable printer with such a large build plate

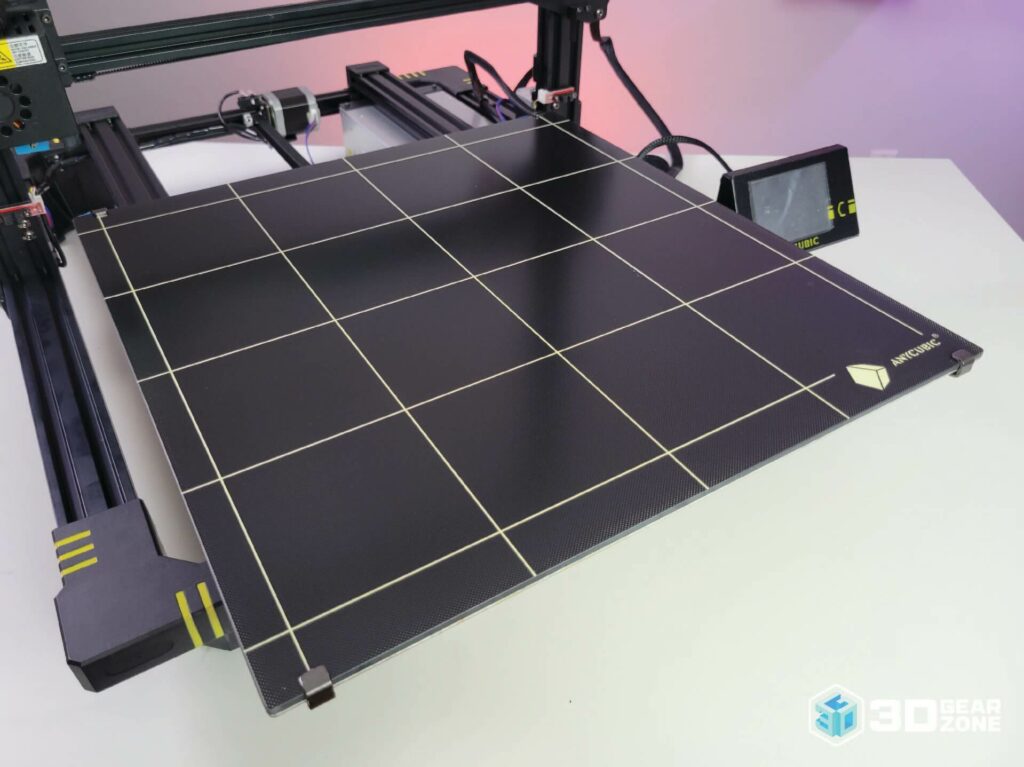

- The Anycubic Ultrabase glass bed provides excellent adhesion when hot and releases prints when cooled

The Cons

- Very loud

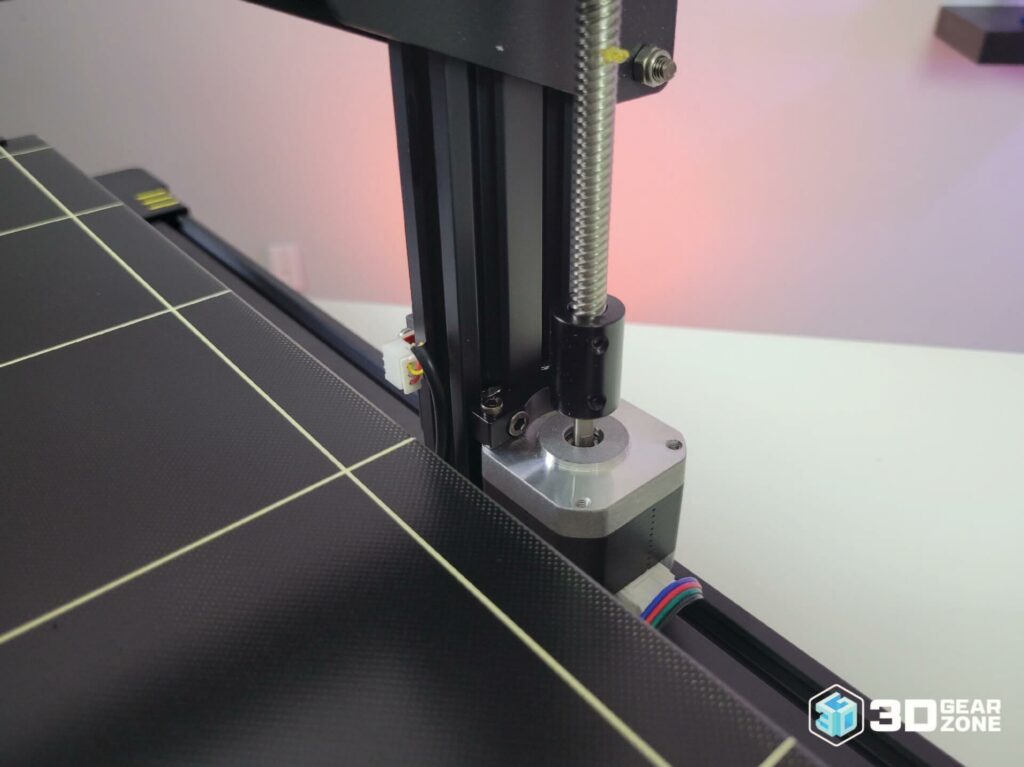

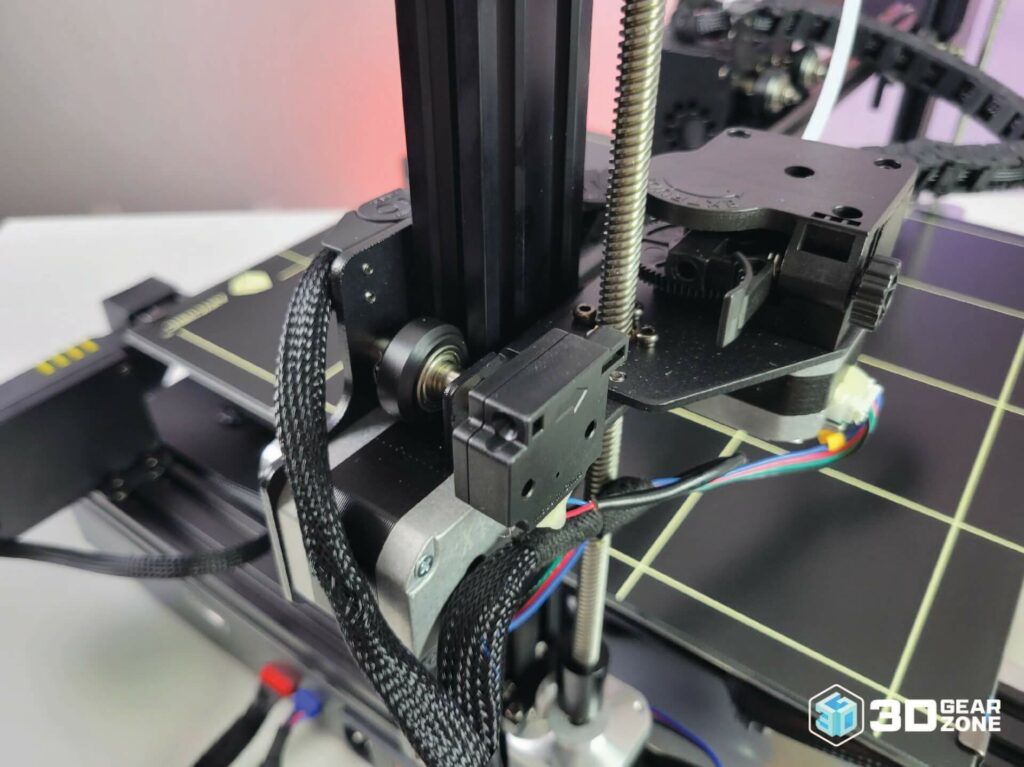

- Print quality is poor due to poor quality extruder clone

- Printer profiles must be made for the Chiron

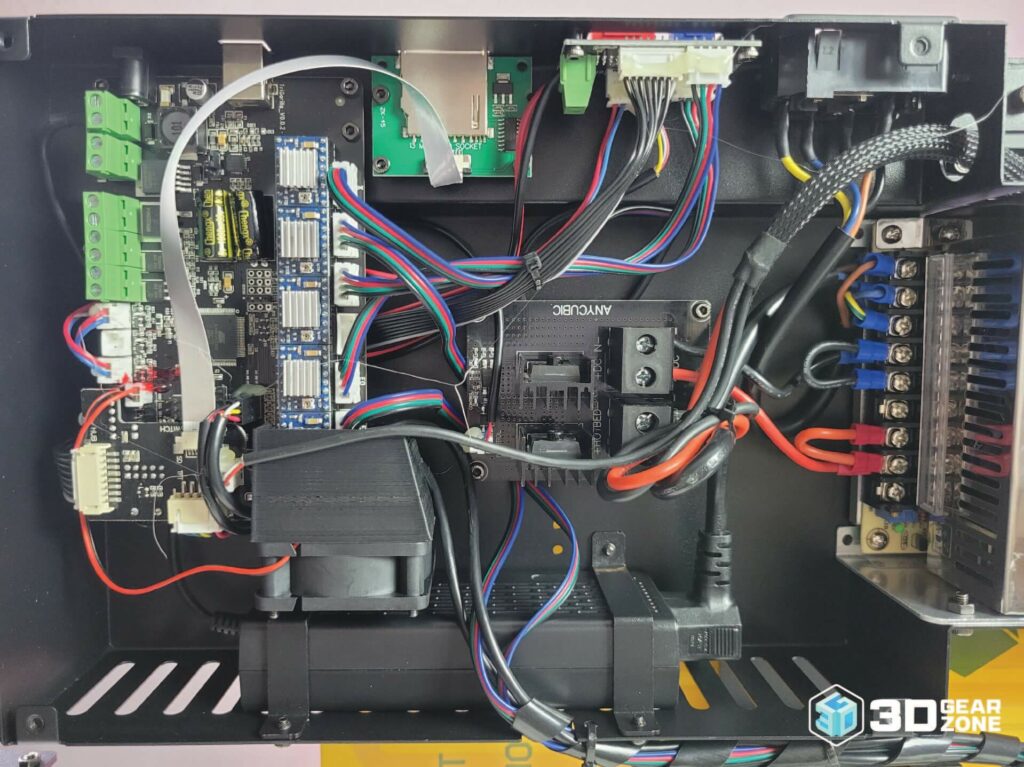

- Overall quality control is poor