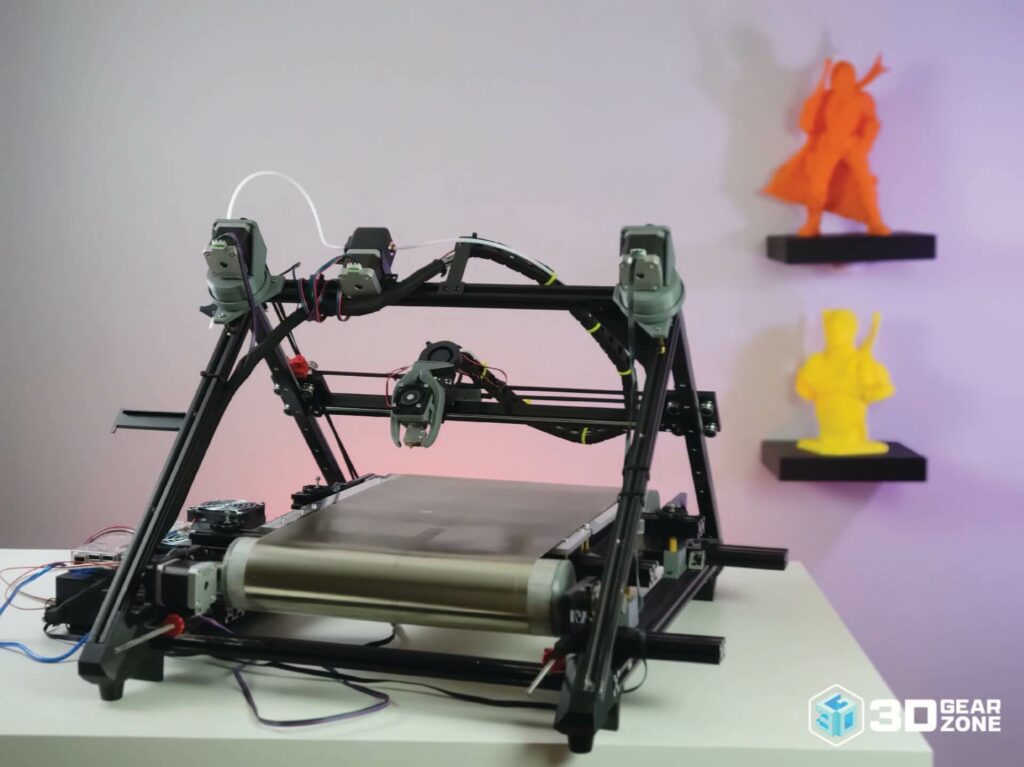

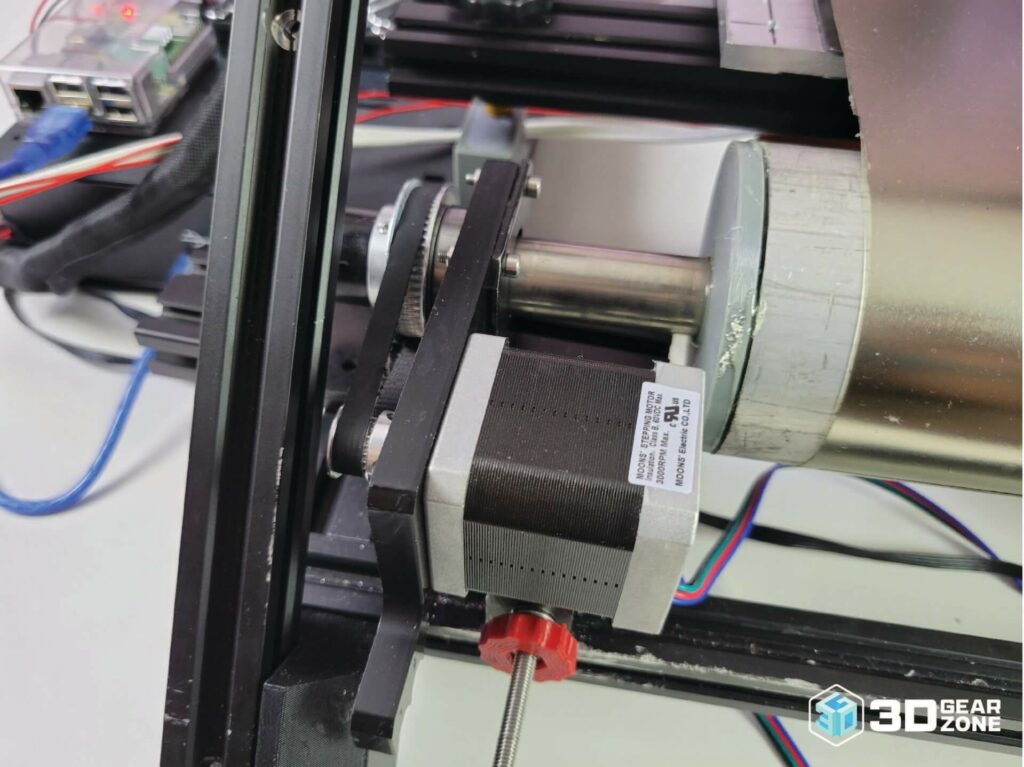

The Belt

The conveyor belt is a unique feature of belt printers and almost all companies are using different materials for their belts. For example, Blackbelt 3D uses a customized carbon fibre belt, the White Knight printer uses a custom stainless steel belt loop, and the Creality CR-30 Printmill uses what appears to be a treadmill belt. The iFactory Factory One uses a similar nylon belt. Each belt material has its strengths and weaknesses, and with the exception of the White Knight printer, each material will leave a rough texture on the bottom of each print.

The belt that was included in the iFactory Factory One is approximately 300mm wide, and iFactory advertised that the Factory One could print as wide as 290mm. The firmware included in our unit was limited to 260mm, and iFactory has released an update to unlock the full 290mm. Unfortunately, we could not test it as our control board stopped functioning early on, and we replaced ours with an SKR 1.4 Turbo with the firmware we wrote on our own. We also could not utilize the entire 290mm build width due to the poor quality heated bed.

Test Printing

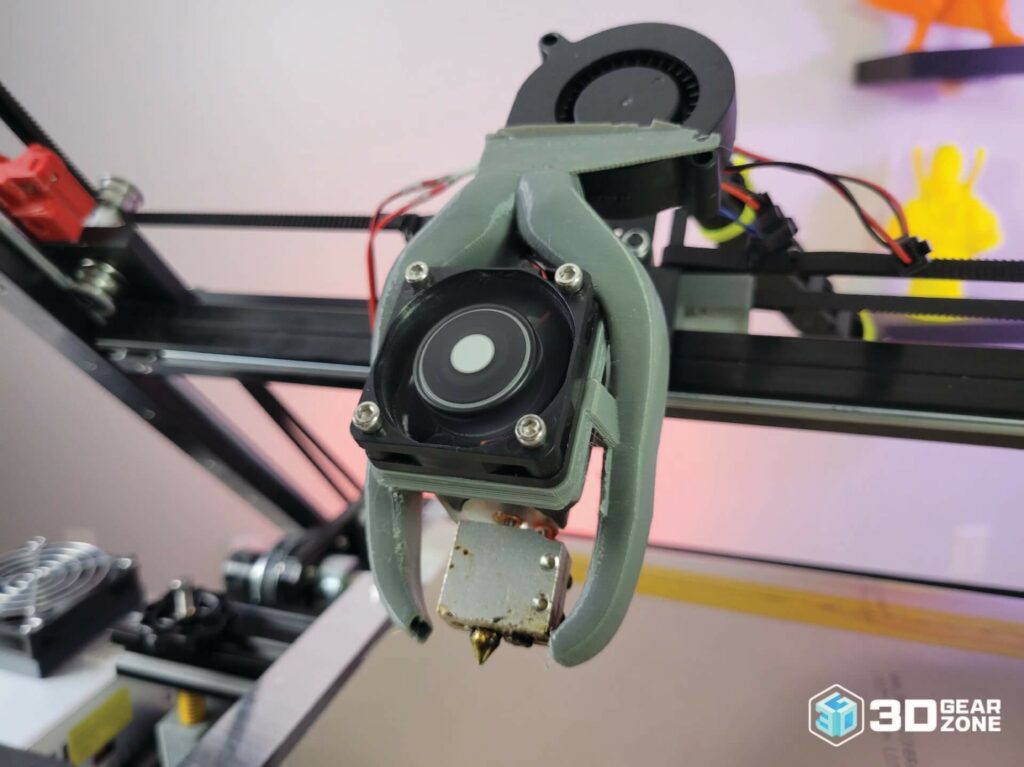

Belt printers have the unique ability to print at a 45-degree angle to achieve printing infinitely in the z-direction. As a result of this angle, many test prints, such as the Benchy, are much more difficult to resolve than a belt printer. We instead tested several different objects that would reflect the unique use cases for the iFactory Factory One.

We wanted to test the iFactory Factory One in 3 major areas: dimensional accuracy, print repeatability and large-scale prints. For these tests, we used Ideamaker 4.1 beta with our own custom 0.3mm layer height settings due to the lack of any included presets.

For dimensional accuracy, we printed a 100mm long square tower on its side. This allows us to test how accurate the motion system of the Factory One is, especially the belt. We noted that the tower measured 20.2mm (l) x 20.2mm (w) x 102.1mm (h). We were pleased that the length and width accuracy of the tower was slightly above average. However, the tower’s height was quite a bit taller than expected. Adjusting the belt motion was a relatively easy fix as it simply required us to input a 2% decrease in the printer’s firmware, and a second tower yielded a height of 100.1mm. Unfortunately, iFactory does not mention any way to adjust the belt accuracy, and new users of belt printers may be unaware of such a fix.

Next, we printed 40 calibration cubes to test how well the iFactory Factory One can handle repeated prints without user intervention. As one of the flagship features of the belt printer, we expected the Factory One to perform this well, and we were pleased to see that the Factory One had no issues printing multiples of the calibration cubes with no issues. We were also pleased to see that the print quality was very good on these calibration cubes. Details were reproduced well, with little to no ringing or ghosting to be found on the print. Layer alignment was also quite good, with nearly no artifacts on the Z axis.

Finally, we printed a few swords to test one of iFactory’s most compelling features: to print extremely long objects. We first printed a narrow and detailed sword. While the print was completed and the sword’s details were reproduced well, we noticed that the sword was warped halfway through the print, resulting in a bowed print that does not lay flat on a flat surface. We decided to print a much wider sword to take advantage of the iFactory Factory One’s wide print area. In our opinion, this would be the killer feature of the Factory One over Creality’s CR-30 Printmill, as the Printmill’s much smaller build width would prevent it from printing such a large object. Unfortunately, the iFactory Factory One warped the sword so much it could not complete and failed on multiple tries. We eventually had to abandon our attempts at printing this object.

Our tests with the iFactory Factory One left us with very mixed feelings. It is capable of printing multiple objects with very good quality and is capable of printing some large objects. However, its constant warping of large objects prevented us from completing prints we were hoping that the iFactory Factory One could do.