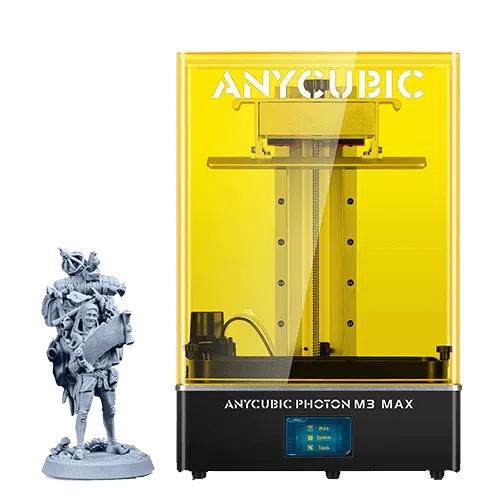

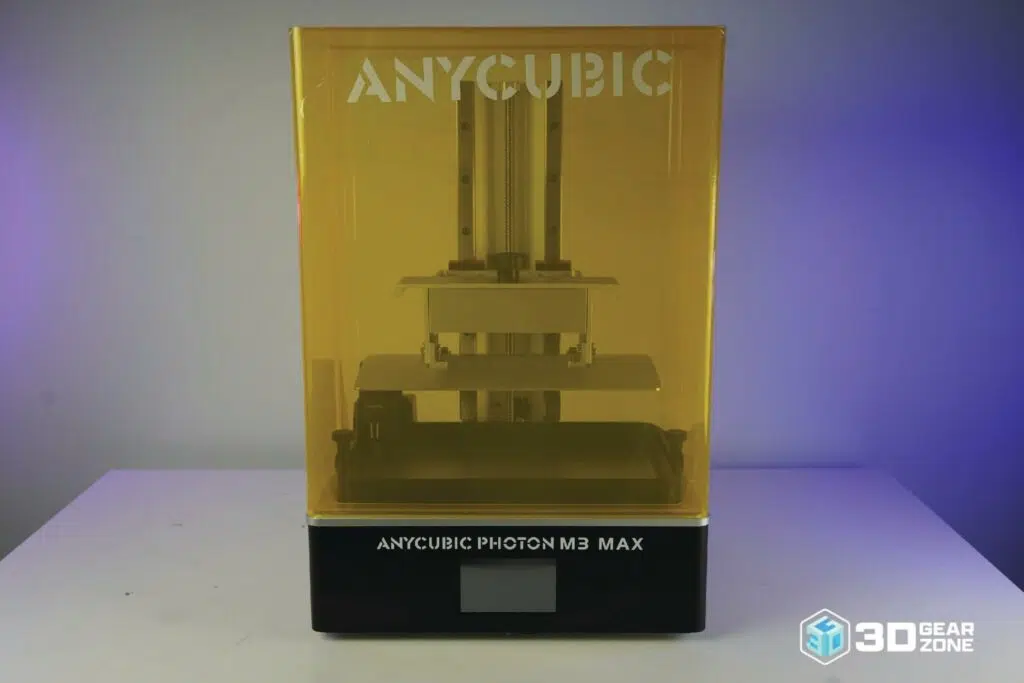

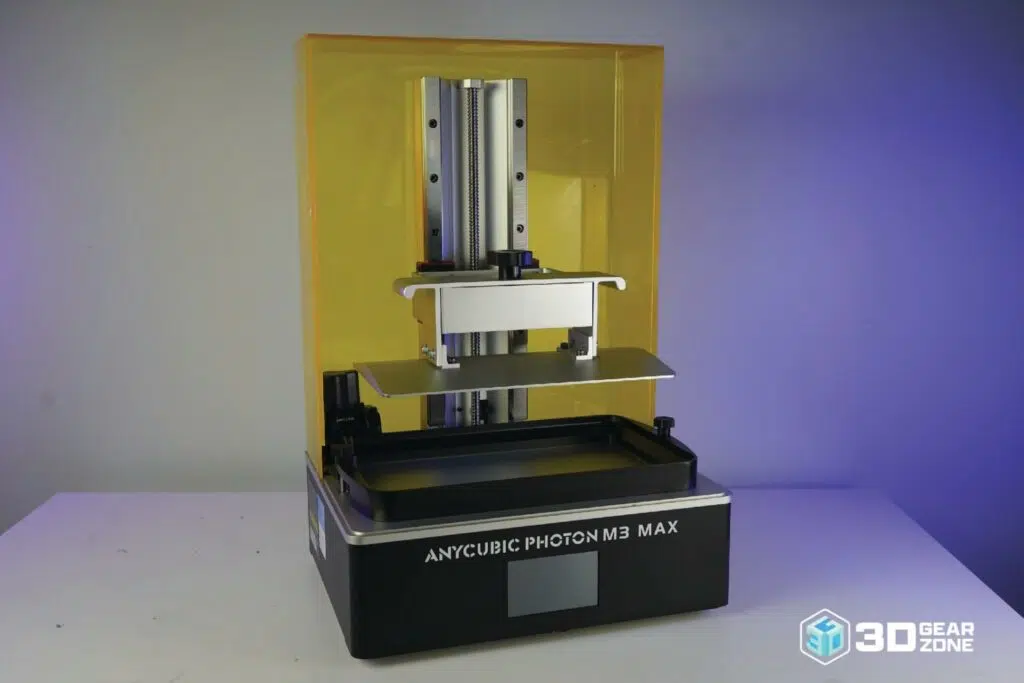

MSLA resin printers are well known for their ability to print extremely fine details, which makes them ideal for crafting tabletop miniatures or intricate jewelry. The M3 Max boasts a 13-inch LCD screen with a 7K resolution, resulting in a pixel size of 46um. Compared to the newest generation of resin 3D printers, which have pixel sizes ranging from 19um-35um, the M3 Max’s pixel size might seem like a drawback in terms of detail resolution.

To assess the real-world impact of this increased pixel density, we’ll be conducting standardized resin print tests, comparing the models printed on the M3 Max with those from the newest generation of 3D printers. This should help us determine if the enhanced pixel density truly results in noticeable improvements in print detail.

In our tests of the Anycubic Photon M3 Max, we used the supplied Anycubic ABS 2.0 resin. You can check out how well the Anycubic ABS 2.0 resin stacks up against the best resins we have tested here.

We tested the Anycubic M3 Max in three major areas: the ability to resolve detailed models, Z height consistency, and UV exposure consistency across the whole build plate.

To evaluate the Anycubic M3 Max’s ability to produce highly detailed models, we conducted a series of print tests, both large and small. These tests included the creation of various organic models like a 28mm tabletop miniature and a dragon bust, an inorganic robot, and a house that featured a mix of organic and inorganic details.

When it came to printing small, intricate details, the printer performed exceptionally well, and the 46um pixel size didn’t leave us wanting finer resolution. One notable advantage of the M3 Max was its enormous print volume, which allowed us to complete all of these test prints in a single print job. With smaller printers, this would have required multiple print runs.

The dragon bust turned out exceptionally well, showcasing all its scales, teeth, and intricate details with flawless reproduction. Similarly, the robot figure displayed impressive print quality, featuring smooth surfaces and a lack of common pixel artifacts seen in printers of this generation. The 28mm scale miniature also printed great, with most of its details printed correctly. However, when compared to the latest generation of 3D printers, the tiny details found on its chest are noticeably softer. Still, we think that situations like these will only manifest on extremely tiny and detailed models.

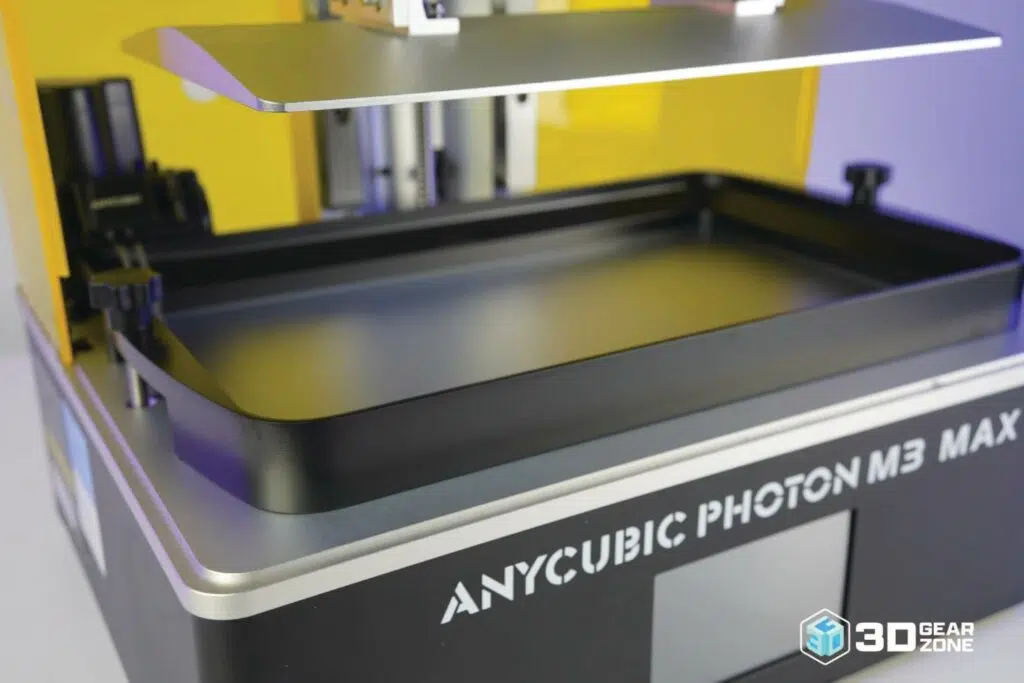

We later printed a series of detailed tiles across the Anycubic M3 Max to test how evenly the UV light is distributed across the build plate. Anycubic markets its M3 Max with an 84-LED matrix array to ensure that light is evenly distributed across the build area. If the light distribution is uneven, then details on the edge of the build area will look different compared to the details in the middle.

Like the 28mm miniature, the details on our test tiles were noticeably softer than the latest 12K resolution machines. Still, we noticed that the tiles remained consistent across the entire build plate, which validates Anycubic’s claim of even light distribution.

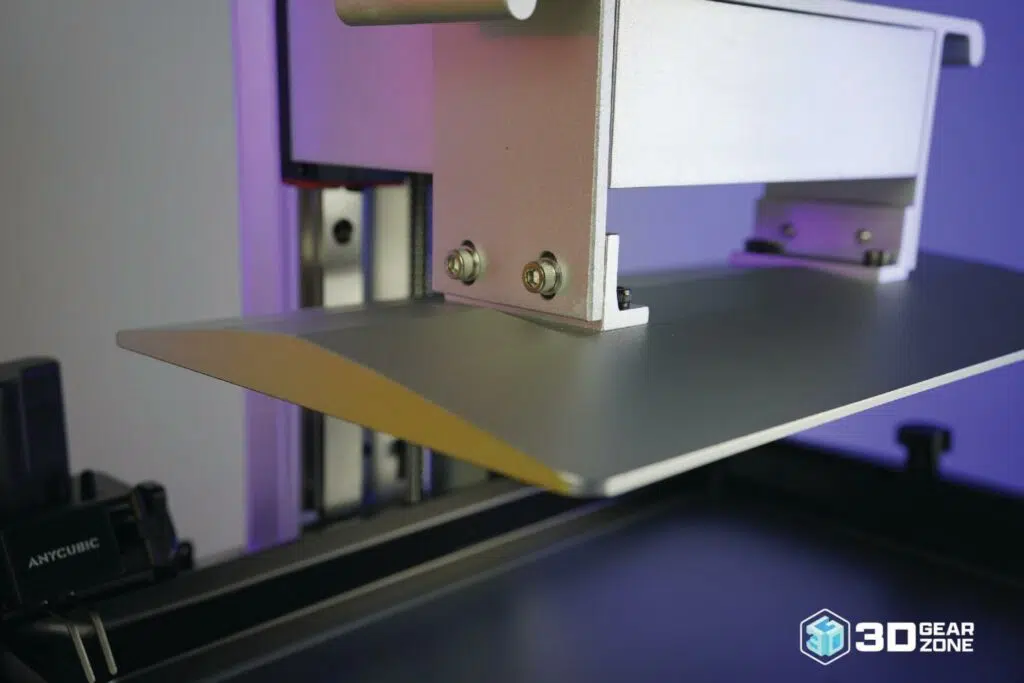

We were not satisfied just printing small miniatures. After all, the Anycubic Photon M3 Max was designed to print enormous items. We decided to challenge it by printing the entire hilt and handle of a sword from the popular mobile game Genshin Impact to see how the M3 Max would handle a large cosplay print—and the results were really amazing!

The M3 Max had all the details reproduced without a single issue. It’s truly remarkable how far resin 3D printers have come in just a few years when the majority were limited to the tiny 100mm build height of the original Anycubic Photon.

The big question here is how well the M3’s 7K resolution compares to the newer 9K or 12K resolution LCDs found in machines like the Anycubic M5 or the Elegoo Mars 4 Ultra. These newer machines boast pixel sizes ranging from 19um to 35um, significantly smaller than the M3 Max’s 46um. On paper, this should mean the newer machines can produce more detailed prints.

Based on our tests, however, there was not a significant difference in most prints when comparing the M3 Max to the latest models from both Anycubic and Elegoo. There were some minute details noticed on the 28mm miniature, and the tiles appeared slightly softer when printed on the M3 Max. But again, we must emphasize that the M3 Max is marketed for larger prints, and differences between the resolutions do not significantly impact the output print quality.