The Pros

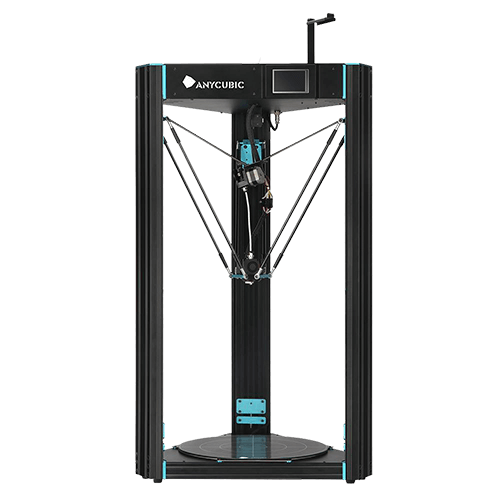

- One of the biggest consumer delta printers that is available

- The Anycubic Ultrabase glass bed provides excellent adhesion when hot and releases prints when cooled

- Uses a full sized SD card instead of a microSD card

The Cons

- Very loud

- Poor print quality due to poor quality control in extruder and arms

- Little community or company support