The Pros

- Good print quality

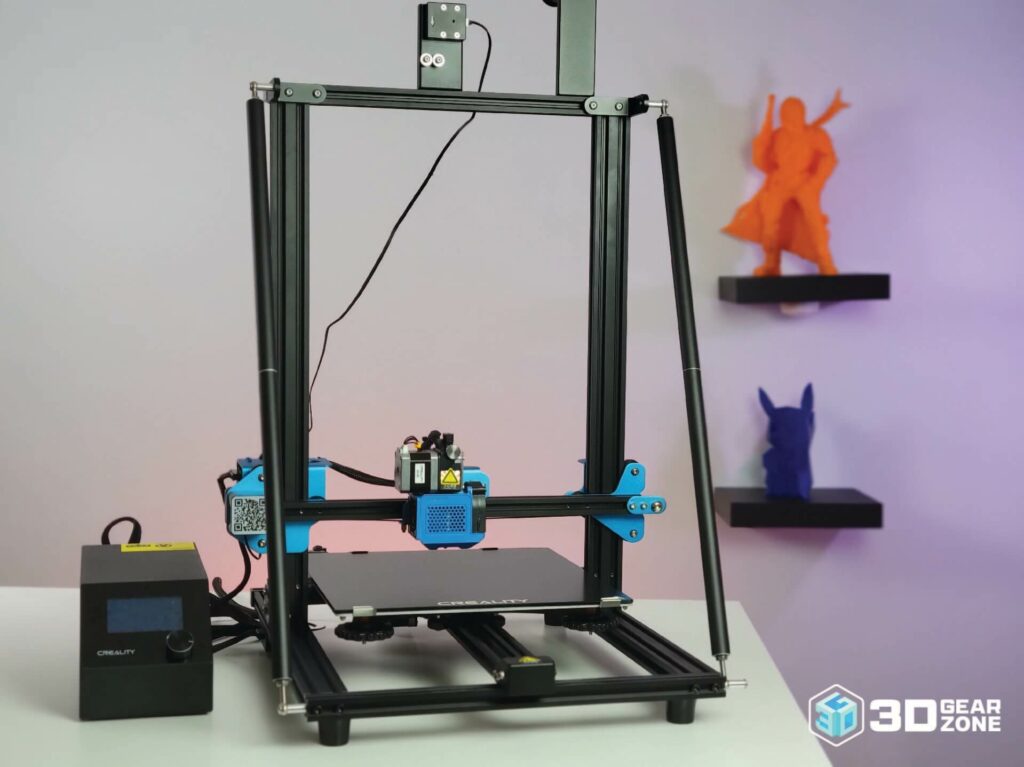

- Huge community and retailer support

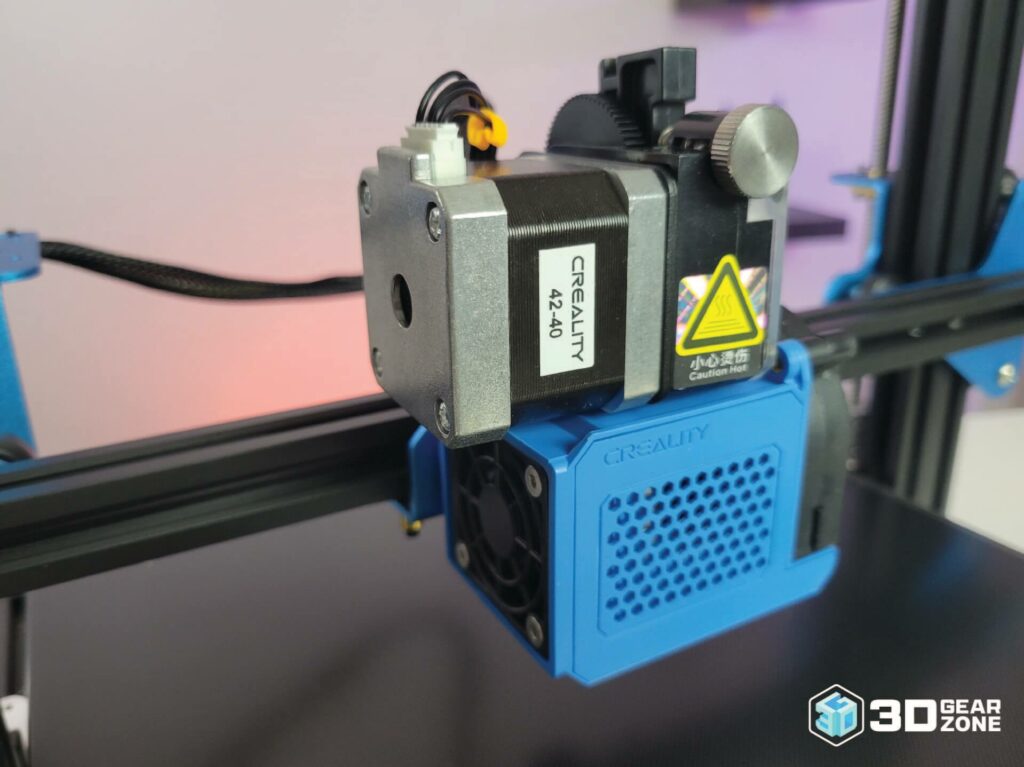

- Equipped with direct drive extruder

- Easy to upgrade to automatic bed levelling

The Cons

- Very dated printer experience

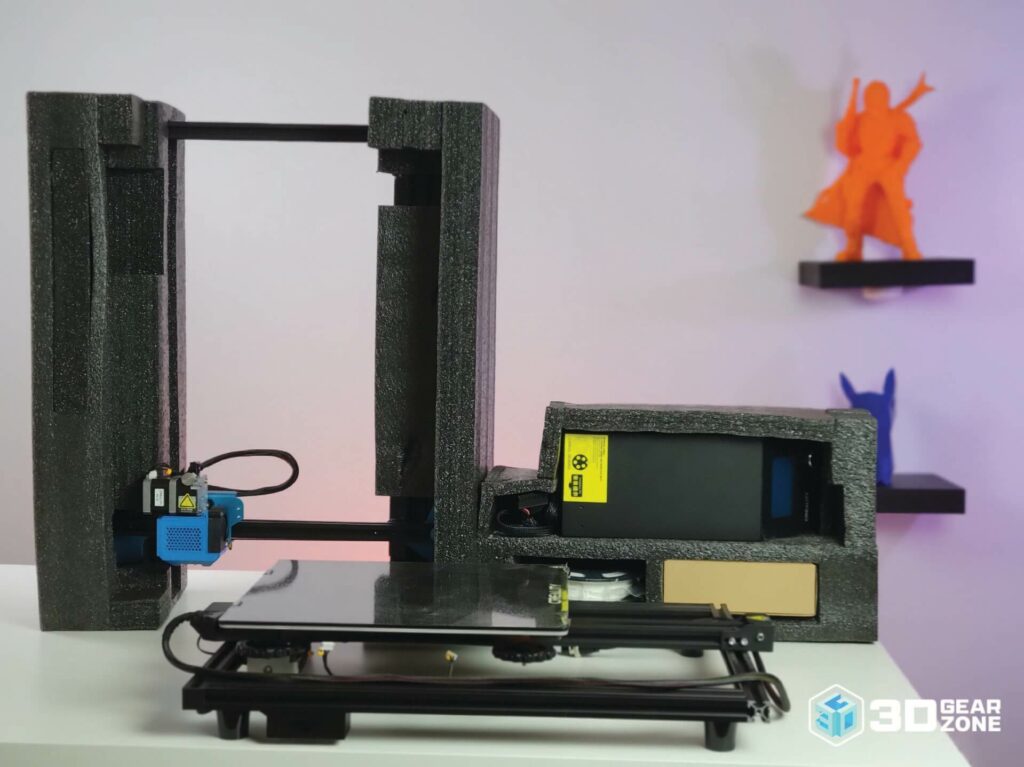

- External control box is a failure point and presents a usability issue

- Must print slower due to the direct drive extruder and light frame

- More expensive than its competitors